Overview

Alabama Power, a part of Southern Company, one of the United States’ largest producers of electricity, operates four utilities with Alabama Power being the second largest within the company. Over 1.4 million homes, businesses and industries in the southern two-thirds of Alabama count on Alabama Power’s reliable electricity supply and service. More than 78,000 miles of power lines carry electricity to customers throughout 44,500 square miles.

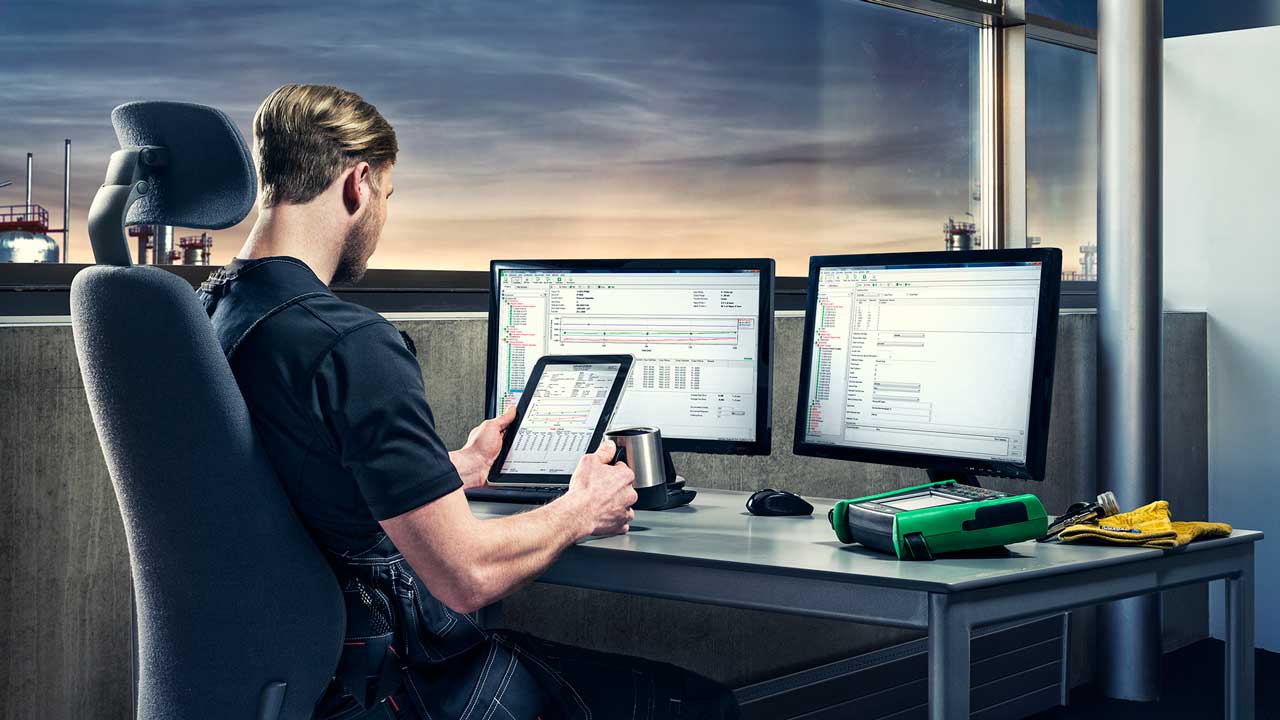

The process control of instrumentation at Plant Miller is managed by two departments. The instrument and control (I&C) department at Plant Miller is made up of engineers and I&C specialists responsible for maintaining the distributed control system (DCS). The electrical and instrumentation (E&I) department includes journeymen responsible for maintaining the plant’s process control instrumentation. The journeymen use portable calibration equipment to make adjustments on site.

The instrumentation and importance of calibration

The majority of the pressure, temperature and level transmitters at the plant come from Endress&Hauser, Rosemount, and ABB. These also include switches, PDITs, RTDs and thermocouples. All instrumentation is classified into two categories; Critical or Balance of Plant (BOP). Although BOP instruments are tasked with taking important measurements, they do not significantly impact the process or cause a substantial safety hazard. However, critical instruments measure process variables that have a significant impact on the process and safety. Some critical instruments can trip the process if they are not operating correctly. In total, there are over 1,000 critical instruments at the plant.

Calibration affects the ability to most efficiently generate power. If an instrument is functioning properly, it improves process control. The better control, the better the end product. Accurate measurements also optimize fuel consumption, the biggest expense for electricity generation. A transmitter out of tolerance could cause other areas of the process to overcompensate by working harder, using more air, more fuel or more gas, affecting the entire process. Consumption affects everything in the long term, including equipment life cycle.

Managing assets and identifying areas for improvement

Faran Rolingson is a Senior Control Engineer in the I&C department at Plant Miller. He manages maintenance projects, including calibration of instrumentation for all of the units and scrubbers. Rolingson is responsible for setting up the job plan and calibration routes, which occur during routine, yearly plant outages when all of the standard calibrations are performed.

When Rolingson joined Plant Miller, calibration was a very manual process. Single function calibrators were used, and meant the E&I journeymen also had to carry a multi-meter and communicator into the process area. It was challenging for the journeymen to follow their routes while carrying the multiple tools required during high-activity outage periods. Elevators were also forced to capacity, directly impacting both safety and productivity.

All information and documentation was paper-based, making it time-consuming to gather and also introducing the risk of human error. Calibration results were manually recorded using pen and paper. Routes were decided by reviewing printed maps and drawings. The routes were based on the plant systems, which meant a route could start with a calibration on the highest elevation, followed by the next calibration on the lowest. This required the journeymen to traverse up and down 13 floors with equipment, a highly inefficient workflow. The journeymen would also have to refer to printed drawings to locate instruments, adversely impacting productivity during time critical outage cycles. The paper-based nature of the plant’s data and documentation was extremely time consuming and labor-intensive.

Setting up for success with high standards

Rolingson accepted responsibility for the I&C portion for Plant Miller’s implementation of the company-wide SOE. It was an opportunity to centralize information and simplify the process, improve accuracy, save time, create a safer environment and make the work easier for everyone. The SOE requires plants to use an electronic database and documenting calibrators as the foundation of an automated instrument calibration program. Furthermore, the documentation system must be enterprise-level, providing the ability to be deployed over the corporate network and the capability to integrate to the company’s computerized maintenance management software, Maximo. With an impending internal audit, Rolingson had to quickly conduct a GAP Analysis to assist in evaluating various solutions on the market.

Rolingson first evaluated the calibration equipment in service and observed the accuracy specifications did not provide an acceptable Test Uncertainty Ratio (TUR) to the more modern instruments being calibrated. In evaluating procedures, traditionally test procedures consisted of 5 points up and prevented any instrument hysteresis from being identified and documented. Rolingson also found instrument location information was only contained in printed maps and not easily accessible. This required gathering as much detailed instrument information as possible and converting the data to electronic format using an Excel and Access database in order to scale requirements for potential solutions.

After researching different vendors, Beamex was the only solution offering the all in one integrated solution (hardware & software) meeting all requirements in the GAP analysis. Rolingson chose the Beamex integrated calibration solution, including Beamex MC6 advanced calibrator/communicators, temperature blocks, pumps, and CMX professional calibration management software.

Superior functionality

There were some instances where the information available for an instrument could not be verified or was somewhat incomplete. To resolve this, journeymen used the MC6 HART communicator to map data from the instrument into a tag-based format on the MC6, perform a calibration, then, create the instrument and calibration results in the database upon upload. This method allowed for an extremely efficient way to establish tags in the database with a very high degree of quality. Additionally, having all instrument data in a central, electronic database makes the planning function much more efficient. The plant’s instrumentation is organized in a hierarchical structure which makes development of highly optimized routes quick and easy.

The MC6 multifunction calibrator/communicator allowed the journeymen to reduce the numerous pieces of equipment required to a single, multifunctional unit. Managing only one piece of equipment improved the safety and efficiency of the calibration work. The journeymen found the MC6 very easy to use. The big, color touchscreen made it easy and intuitive to navigate through the different functions of the MC6, and each functional mode is easily accessed from the “Home” screen. The plant SOE requires both AS FOUND and AS LEFT data to be documented which required two tests be conducted. The MC6 provides the option to save the AS FOUND data in the AS LEFT table if no adjustment to an instrument is done, another feature of the MC6 that has reduced the amount of time required to be compliant with procedures.

The temperature and pressure switches are critical to safety in the plant. Calibration relied heavily on the skill of the journeyman to precisely determine the measurement upon physically observing switch actuation and de-actuation. This critical calibration is now completely automated with a high degree of accuracy using the MC6. There is now no reliance on the journeyman to observe the measurement and switch action simultaneously, making for a high quality calibration and ultimately much safer operating environment. Being a member of HART Communication Foundation, Beamex diligently makes instrument manufacturer’s device descriptions (DD) available for MC6 users to download and apply themselves. Previously, it was quite disruptive and time consuming to search for the correct DD for their handheld communicator.

Realizing the benefits, return on investment

“When you are under the gun, you need to know whether it was the process, the transmitter or controls,” Rolingson states. The high accuracy specifications of the MC6 allowed them to exceed industry-standard TURs which give the automation engineers confidence that process control instrumentation is performing as designed. The older measurement standards had an acceptable TUR when they were initially procured years ago, but the modern instrumentation in service today has evolved to be more accurate. The high accuracy of the MC6 provides a higher quality of control, improved process efficiency, and optimized fuel consumption.

“Tasks that would take a month to two months to complete, could be performed in a few weeks,” explained Rolingson. “Time is money.” By removing all the manual steps in the workflow, and eliminating all the paper from the dataflow, the plant has realized a documented time saving from 70%, even up to 75% in some cases, on calibrating pressure transmitters and pressure switches. Time is of the essence during an outage, so this time savings allows technicians to maximize the amount of work accomplished in the shortest amount of time, while effectively performing vital tasks and managing workflows.

Eliminating inefficient calibration work greatly reduces the risk of outage schedule overruns and delays of start-up procedures. For Alabama Power and Southern Company, this means lowering their cost while maximizing revenue generation.