Summary

As part of the modernization of EDF Energy’s power plants, EDF Bouchain became the first new generation combined cycle power plant in the world. Because the outage period at Bouchain is only 3.5 weeks, carrying out more than 400 measurement checks with a small labor force is a major challenge. In the interests of quality, safety and durability of the installations, it was essential for the automation department to be equipped with a calibration management system capable of meeting its strict requirements. The Beamex integrated calibration system was an obvious choice in terms of automation, time-saving, monitoring, traceability and confidence in the data produced.

Challenges

Because the outage period at Bouchain is only 3.5 weeks, carrying out more than 400 measurement checks with a small labor force is a major challenge. In the interests of quality, safety and durability of the installations, it was essential for the automation department to be equipped with a calibration management system capable of meeting its strict requirements.

Integrated calibration system

The Beamex integrated calibration system was an obvious choice in terms of automation, time-saving, monitoring, traceability and confidence in the data produced.

The services provided by Beamex made it possible to prepare all the data, procedures and tasks to be performed so that the service provider company was operational from the first day of the outage period.

Read the full EDF Bouchain customer case story

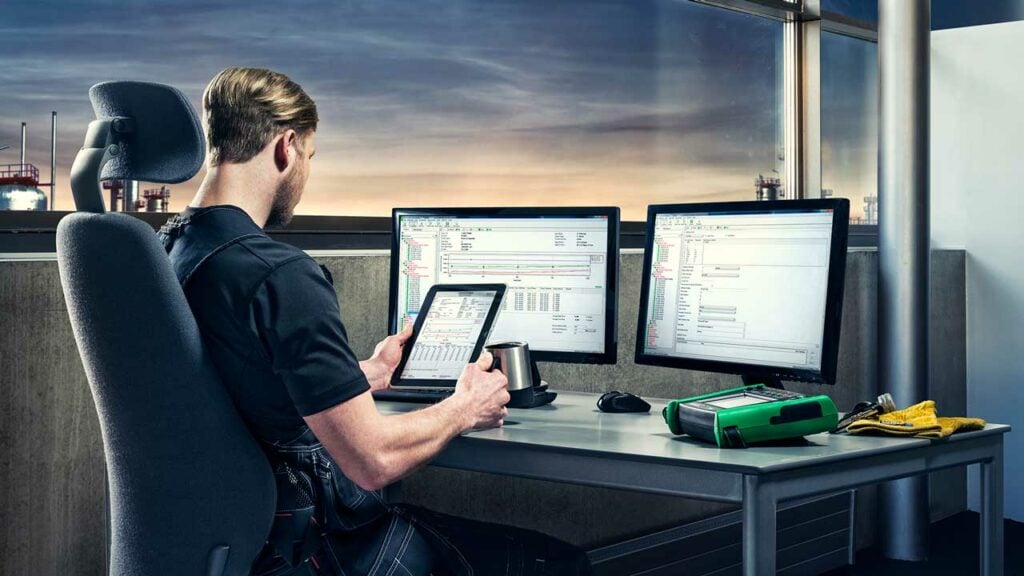

Multifunctional Calibrator

The multifunctional features of the MC6 calibrator and communicator drastically reduced the amount of equipment that each technician needed to carry to a single device. The MC6 made it possible to carry out pressure and temperature calibration, as well as communication with HART and Foundation Fieldbus transmitters. As a result, handling was greatly simplified because users only needed to become familiar with one interface.

The precision of the MC6 calibrator also halved the number of pressure modules needed at Bouchain. In addition, the reliability of the results transmitted will allow EDF to prepare its future audits calmly and confidently.

Main Advantages

- Turn-key solution

- Durability thanks to maintenance agreements

- Support and customization

- Ease of use

- Local support

- Time-saving

- Controlled maintenance cost

- Easy and secure access for the service provider company