Summary

For Westland Milk Products, one of New Zealand’s largest dairy producers, finding a better way to calibrate has boosted the company’s profitability and strengthened their ability to ensure quality and excellence. At the heart of their Beamex calibration solution is Beamex software packages, which has helped to slash calibration times by a staggering 75%.

Improving efficiency the number one driver for change

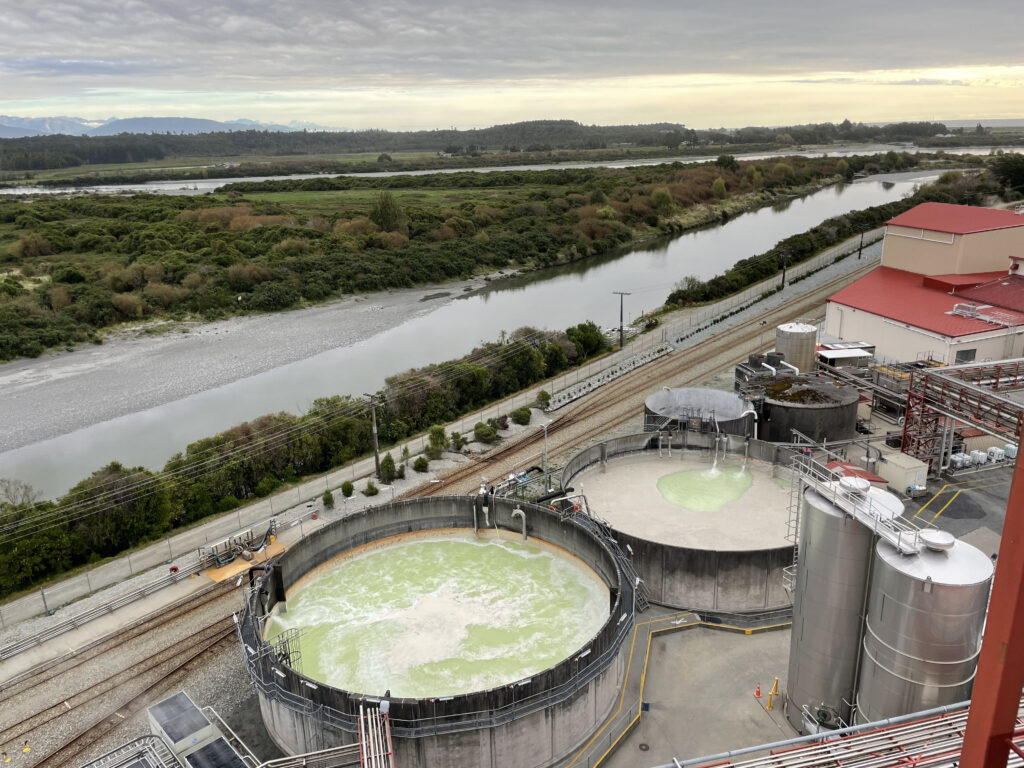

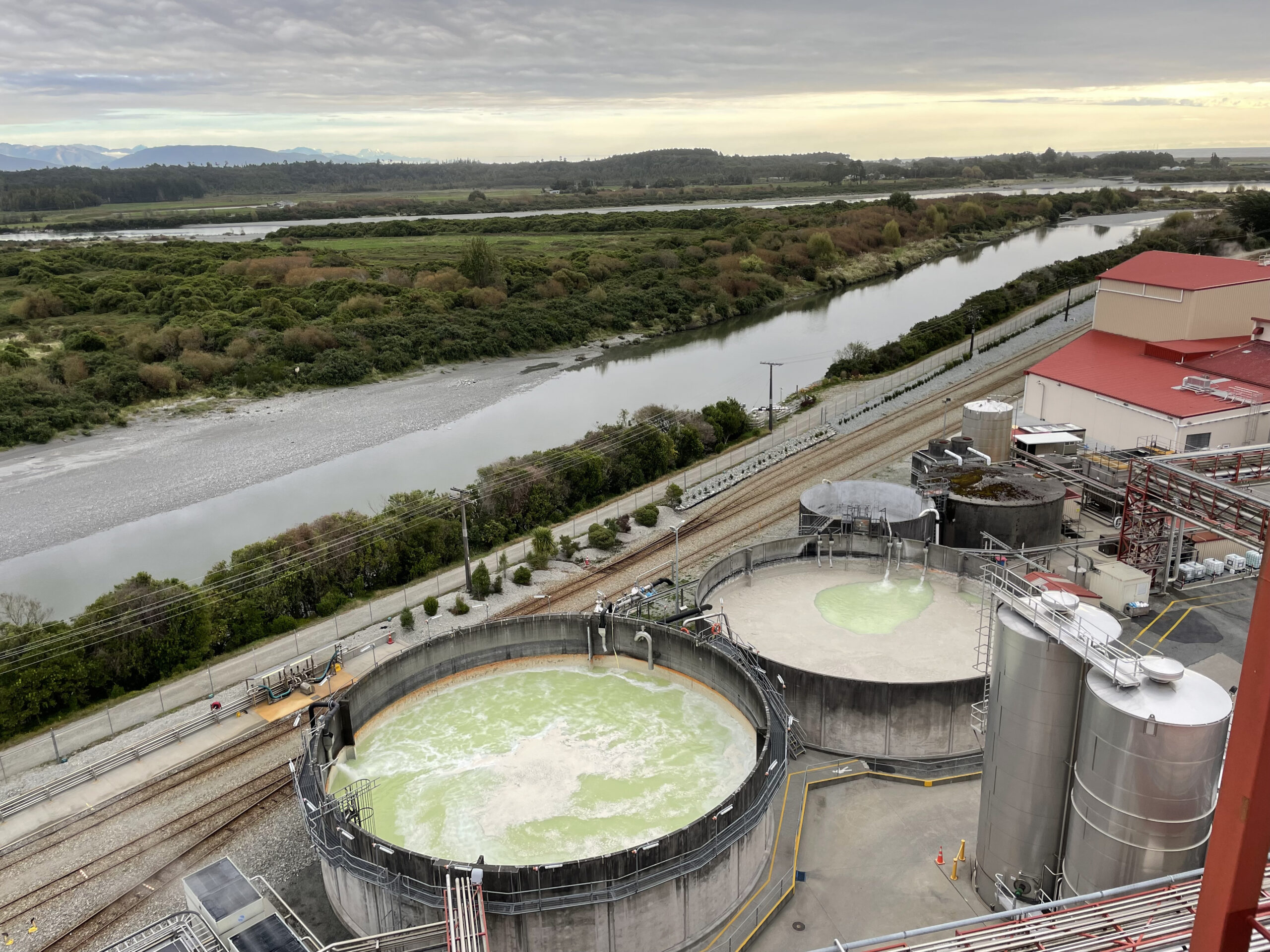

Based in Hokitika on the rugged west coast of New Zealand’s South Island, Westland Milk Products (WMP) is a company with a long and distinguished history. Established in 1937 as Westland Co-operative Dairy Company, today the company is the fourth largest dairy processor in the country.

Until two years ago WMP had been following a largely manual calibration process, which Lead Calibration Technician Zandre Klopper knew had room for improvement, not least in terms of its efficiency. He and his team were spending almost as much time on system management as they were on performing calibrations.

Bridging the gap between calibration and maintenance management systems

To create a fully connected calibration system, WMP needed to bridge the gap between their computerized maintenance management system (CMMS) and their calibration management software. Beamex software packages offered the perfect solution. Beamex CMX Calibration Management Software would form the core of the Beamex solution at WMP, with Business Bridge used for connecting CMX and CMMS systems.

WMP also chose to implement the Beamex CENTRiCAL Workshop Calibration Solution – a modular and versatile calibration bench that is tailored to WMP’s specific needs. Beyond improving the efficiency of their work, the Beamex solution has had a significant positive impact on employee well-being and satisfaction. “Almost immediately we could see the lift that the new solution gave the team,” Klopper says. “They were less stressed, less frustrated, and felt a much greater sense of satisfaction with their work. We were all asking ourselves why we hadn’t done this years ago!”

Read the full WMP customer case story

75% increase in calibration efficiency – and that’s just the start

Connecting their calibration system and maintenance management system with Beamex software has delivered across the board for WMP. The Beamex hardware and software make the calibration process much more efficient, with a fully automated process to certificate generation. Manual (as-found) calibration was taking two hours, while with fully automated process the time has been cut to just 30 minutes, saving around 3,000 hours a year.

The extraordinary increase in efficiency means that the project is projected to pay itself back in just four years. In terms of audits and inspections, Klopper points out that the Beamex solution has given WMP an extra edge in the eyes of the auditors and regulatory authorities that they deal with. “The Beamex solution has far exceeded our expectations”, Klopper sums up “From day one of our collaboration everyone has been focused on finding a better way to calibrate, plan, work, learn, and improve.”