For a safer and less uncertain world

Accurate measurement is the glue that holds our communities and societies together, and it affects us all. It gives us confidence that the medicine we take is safe, the water we drink is clean, and the food we eat can be trusted. The industries behind these vital elements of our everyday lives rely on accurate measurement to ensure the safety of their processes, to improve efficiency, and to minimize emissions and waste.

Our comprehensive ecosystem of calibration solutions help to create safer and less uncertain world by ensuring that our customers’ measurement data is trustworthy and traceable, supporting smarter and more sustainable business.

How calibration improves sustainability

Calibrating process instruments on a regular basis using Beamex technology helps our customers to minimize production and energy losses and optimize their processes to ensure they are as efficient as possible. Regular calibration also ensures consistently high product quality.

Sustainable by design

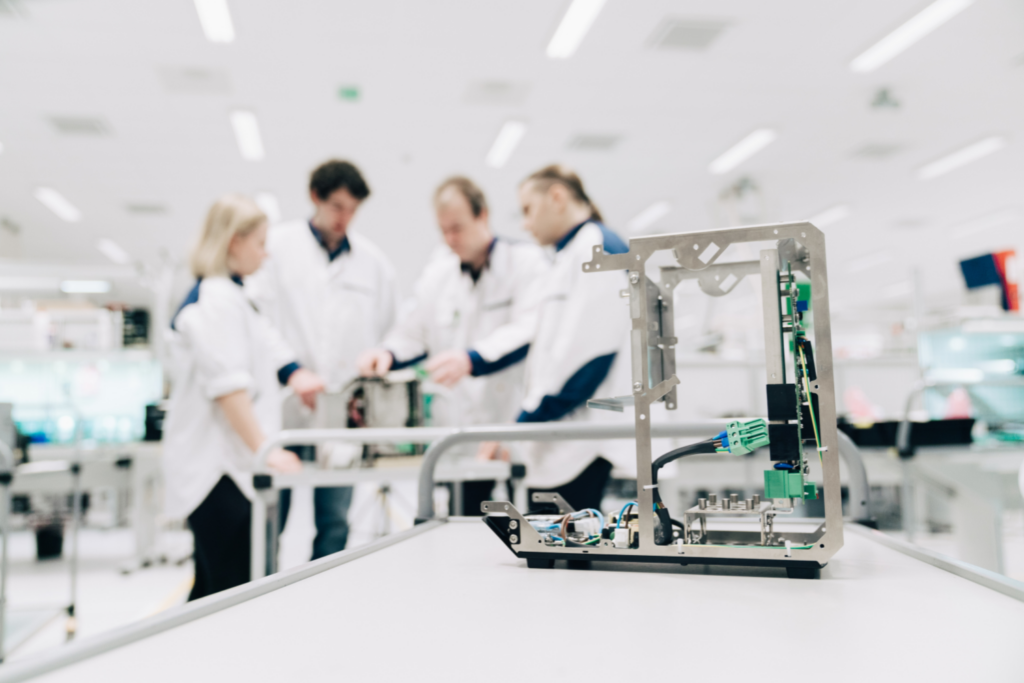

Sustainability is a core component of the Beamex design philosophy. We want our customers to continue using their Beamex products for many years, so they are designed to have a long service life and to be as easy as possible to repair, maintain, and upgrade. This supports the circular economy and conserves valuable natural resources.

It is estimated that the decisions made at the product design stage directly result in 80% of a product’s environmental impact and 90% of its manufacturing costs. Extending the life and usability of electrical products is one of the most effective ways to reduce our carbon footprint and conserve valuable, irreplaceable natural resources such as rare earth elements.

Circular economy

Beamex products are designed to support the circular economy by being reliable, easily maintainable and repairable, compatible with a wide range of other plant equipment, and easily upgradeable. These factors ensure a long product lifecycle, reduce waste, and help to conserve natural resources.

Reliable

We speak about Beamex products being ‘sustainable by design’ because they are designed and built to be reliable, using only the highest-quality parts and following a stringent quality-control process during manufacturing that ensures they have a long operational lifespan.

Maintainable

We provide professional recalibration services and convenient service plans to help you keep your calibration equipment operating at its full potential throughout its lifetime.

We also provide a wide range of spare parts for Beamex products including complete spare-part kits, making it easy to extend the lifespan of your equipment and ensure it remains in good working order.

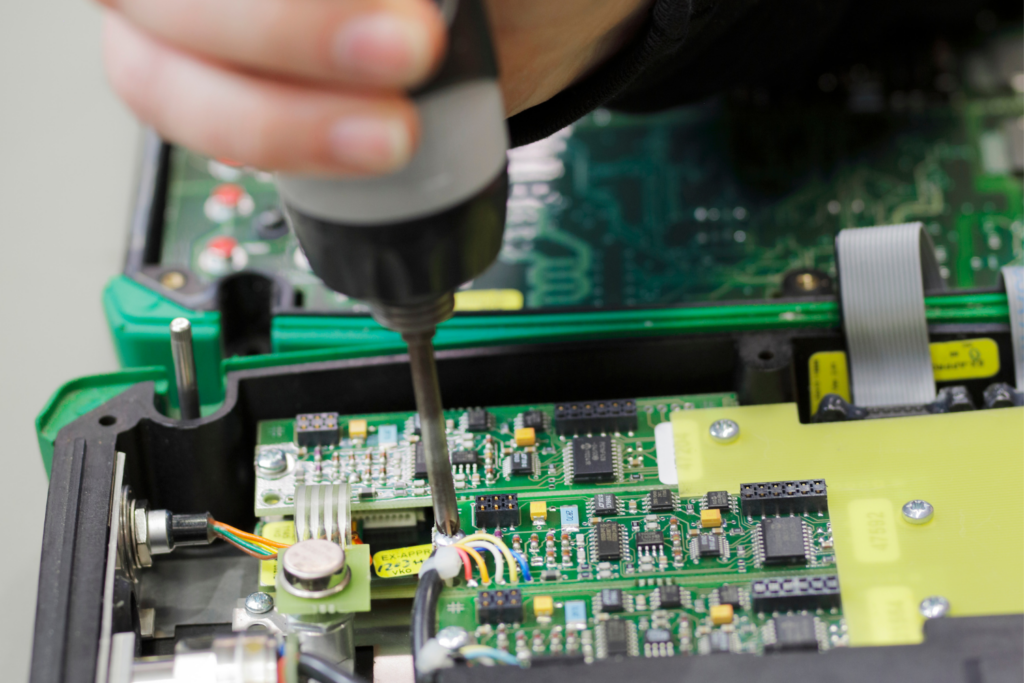

Repairable

Our skilled service technicians can repair Beamex products to the highest standards of quality to ensure that they continue to serve you for many years.

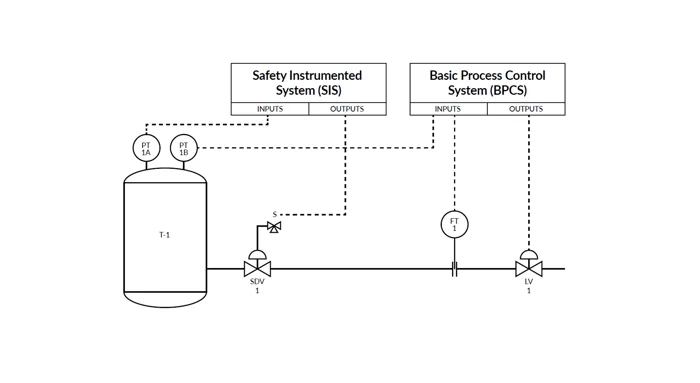

Compatible

Our versatile products can be used to perform everything from pressure to electrical and temperature calibrations and more and can be delivered with HART, Foundation fieldbus, and Profibus communication capabilities.

Upgradeable

The versatility and longevity of Beamex solutions can be enhanced by adding hardware and software modules including firmware updates. This enables Beamex products to be used in a variety of different applications over their lifetime, avoiding the need to purchase new equipment when your requirements change.

Digitalization as an enabler of sustainability

We see digitalization as a critical enabler for reaching sustainability targets across the sectors in which our customers operate. Through accurate, reliable measurements gathered and managed using digital processes, our customers are better able to monitor and optimize their energy consumption and reduce material waste.

Digitalized calibration

Today, dedicated calibration software is the most advanced solution available to support and guide calibration management activities. At Beamex, by enabling our customers to move into the digital era we help them operate more efficiently, safely, and sustainably.

Together we can find the digital calibration ecosystem solution suitable for your operations.

A better way to a sustainable future

Explore our series of topical articles where we discuss the impact accurate measurement and calibration have on the world and our everyday lives.

Social sustainability

We want to ensure that we, as an organization, are operating in a fair and ethical manner. We embrace a responsibility to sustain fair treatment of our employees, suppliers, and customers. Our aim is that our existence has a positive impact on all levels of society.

We will achieve this through:

Being a responsible employer

We support well-being, lifelong learning and offer a flexible working environment. Regular discussions between the employee and the supervisor are accustomed. We promote equal pay and have anti-discrimination and anti-harassment policies.

Being a responsible partner

We believe in ethical and sustainable sourcing because our supply chain is based on close cooperation with our suppliers. As with our customers, we recognise the value and our responsibility to treat our partners well.

Being a responsible neighbor

We are continuously working to achieve the UN Sustainable Development Goals, including environmental policies and sustainable social impact. We contribute to the local communities in which we operate by supporting local businesses, organisations and schools through donations and partnerships.

Environmental sustainability

Calibration is a critical activity in controlling emissions as emission-related instruments are often associated with a plant’s license to operate. Beamex products are designed to have a long operating life. For example, our customers typically use their Beamex calibrators for over 10 years.

Sustainable sourcing

Through our supply chain management we aim to create sustainable competitive advantage, continuity, and innovation through collaboration. We need to protect our brand image and manage supply chain disruption risks, and we recognize that knowing our suppliers better is a key factor in this regard. Our excellence in a high-mix, low-volume business model depends on effective management of our suppliers and strategic subcontractors.

Standards and policies

EcoVadis rating

EcoVadis has awarded Beamex a rating for Corporate Social Responsibility (CSR) and Supplier Sustainability. The areas covered in the evaluation include the environment, labor & human rights, ethics, and sustainable procurement.

Beamex EcoVadis rating >

ISO certifications

The environmental management system used at Beamex is ISO 14001:2015 certified and the occupational health and safety management system used at Beamex conforms to the

ISO 45001:2018 standard.

Certificates >

Code of conduct

The Beamex global code of conduct describes the principles that guide our employees in making ethical and legal business decisions and the standards we expect our partners to uphold.

Beamex global code of conduct >