Summary

Peñoles Quimica del Rey, the Latin-American based intermediary, operates within the metallurgical-mining and chemical industries and are part of the Peñoles Group, the second largest Mexican mining company and the first Mexican producer of gold, zinc, lead and silver. Peñoles Quimica del Rey maintain their domestic leadership by supplying 56% of the national magnesium sulphate market and are the largest Sodium Sulfate plant in the Western Hemisphere. Despite strong competition, the company is ranked third in the world in terms of their installed capacity of sodium sulphate which is used for the production of detergents, glass and paper.

Calibration is fundamental

Roberto Lopez, the Supervisor of the Instrumentation Department at Peñoles Quimica del Rey explains the role of calibration. It plays a fundamental role in ensuring that our business objectives are fulfilled, measurements are accurate and controlled processes are in place. The precision of the measurements in the different stages of production determines the quality; if we have inaccurate measurements we will have low quality products, but if the measurements remain accurate and correct, we will continue to supply high quality products.

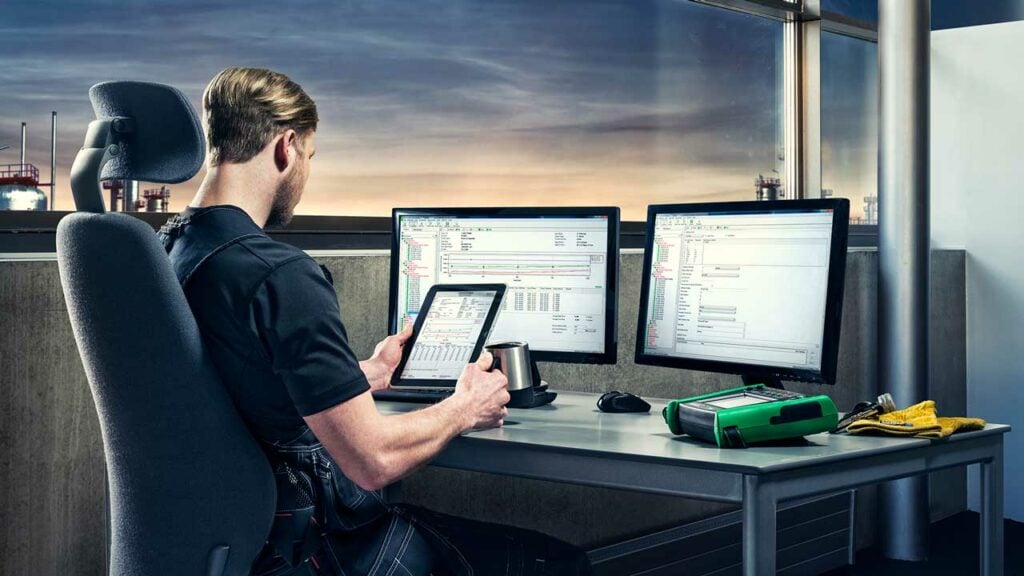

Finding the right equipment

One of the core principals in the decision-making process was inevitably to find an accurate calibrator, but one which also featured documenting functionality and a supporting software solution to aid the process. The Beamex MC6 calibrator was rendered an appropriate choice of equipment for the company, along with CMX Calibration Management Software, to help compliment and streamline the process.

Read the full Peñoles Quimica del Rey customer case story

Efficient time savings

Prior to rolling out with the Beamex product solution, Peñoles Quimica del Rey trialled the equipment and discovered that the time taken to complete the calibration was reduced by two hours. Automatic calibrations using the Beamex POCs and Temperature Blocks, in addition to the automatically generated documentation produced through CMX and the MC6, it has made huge time savings for the company and has significantly enhanced efficiency and productivity within the department.

Significant improvements

The accurate measurements provided with the MC6 in parallel with the integrated software solution continues to help Peñoles Quimica del Rey produce a high-quality product, it reduces the waste of raw materials, cuts costs and reduces their carbon footprint. “Streamlining the process has made huge time savings, enhanced efficiency, maintenance, improved productivity, but fundamentally, it has helped us to achieve our business principals and continue with the delivery of our high-quality products.” Lopez comments.