A better way for workshop calibration

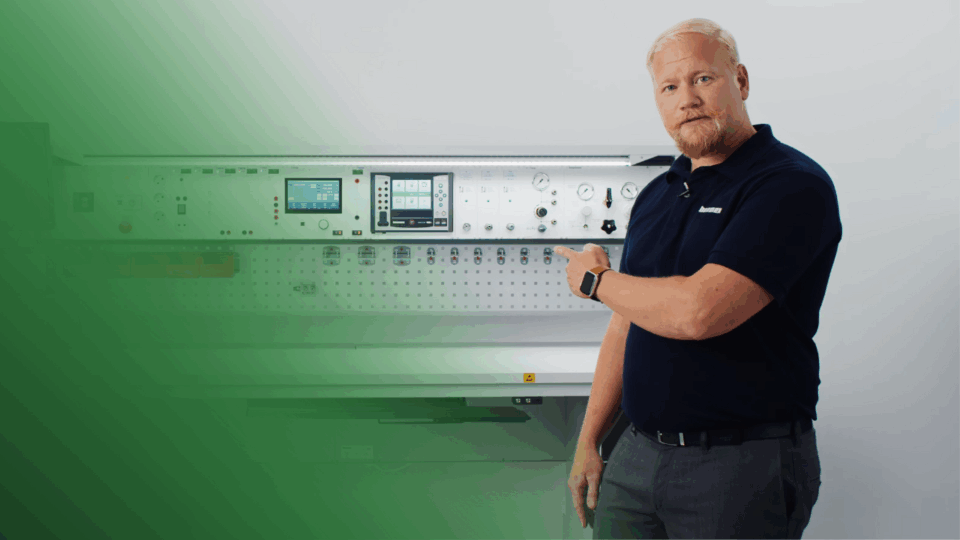

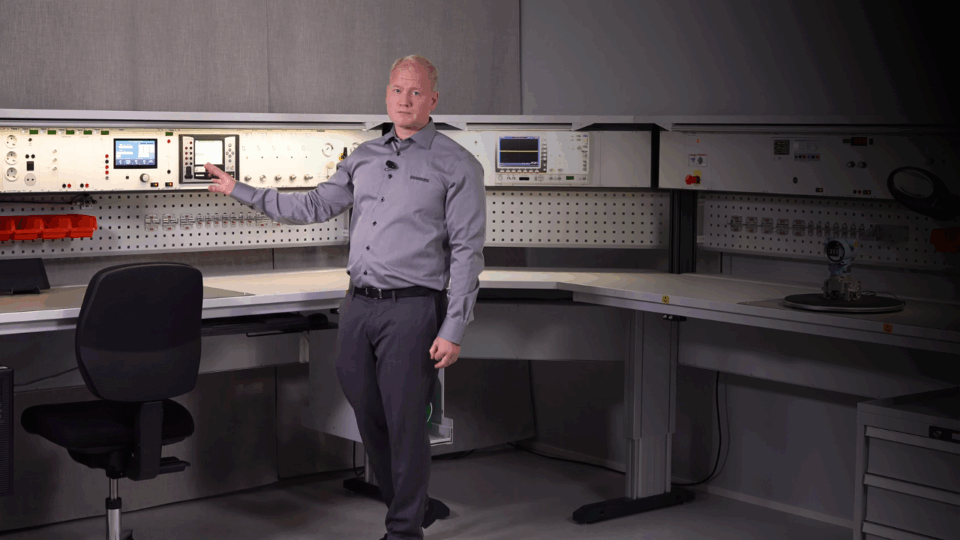

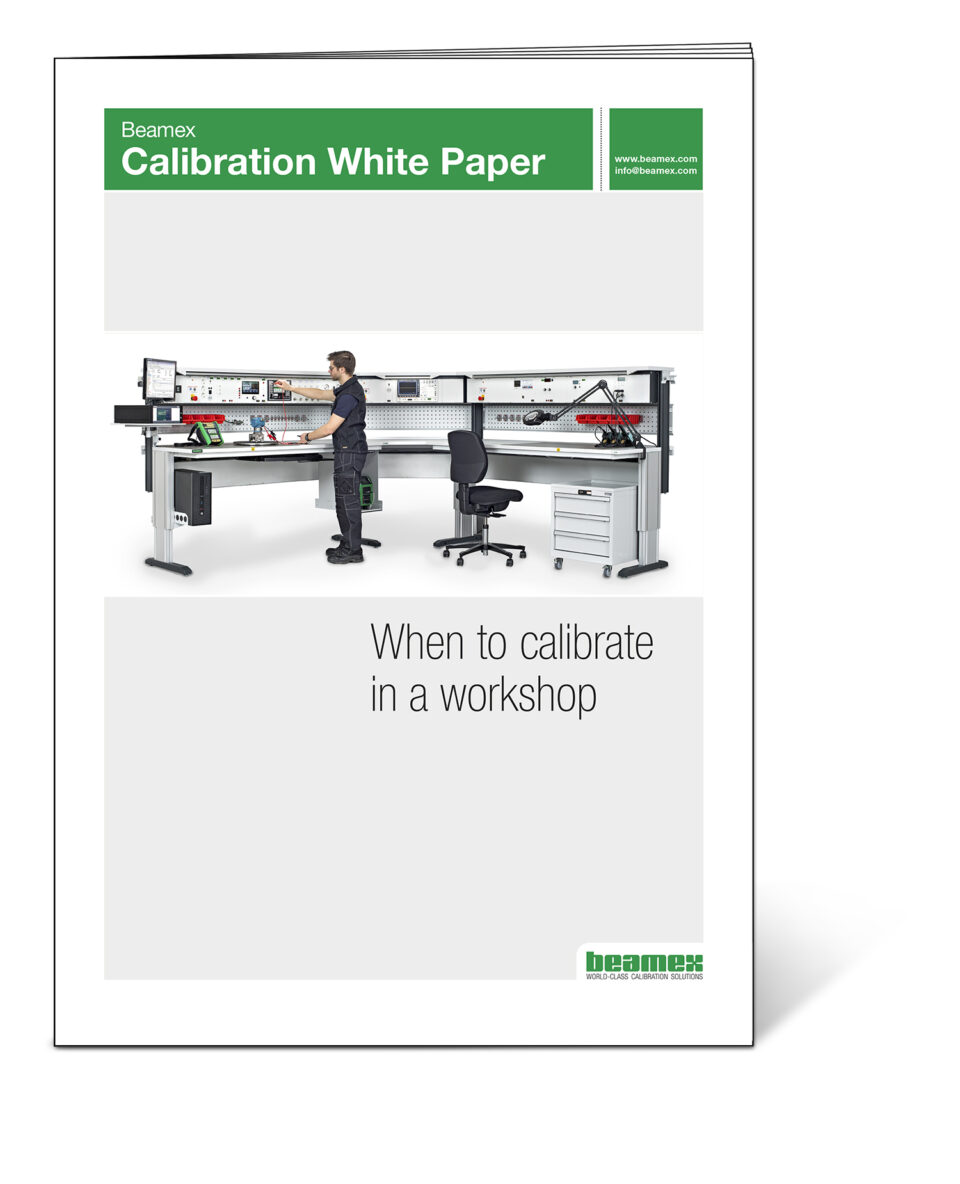

The Beamex CENTRiCAL Workshop Calibration Solution reflects the result of decades of experience providing world-class solutions for the process industries. This standardized yet configurable solution is easy to use, versatile, and ergonomic.

Beamex CENTRiCAL – a central place for all your workshop calibrations.

Modular and versatile

CENTRiCAL is a modular and versatile solution that can be tailored according to your specific needs and is suitable for a wide variety of applications.

Ergonomic

The bench height can be electronically adjusted and all equipment ergonomically located for maximum comfort and efficient working.

Easy to configure

The modular design and ready-made packages make it easy to configure your CENTRiCAL workshop calibration solution according to your specific needs.

Electrostatic discharge protected

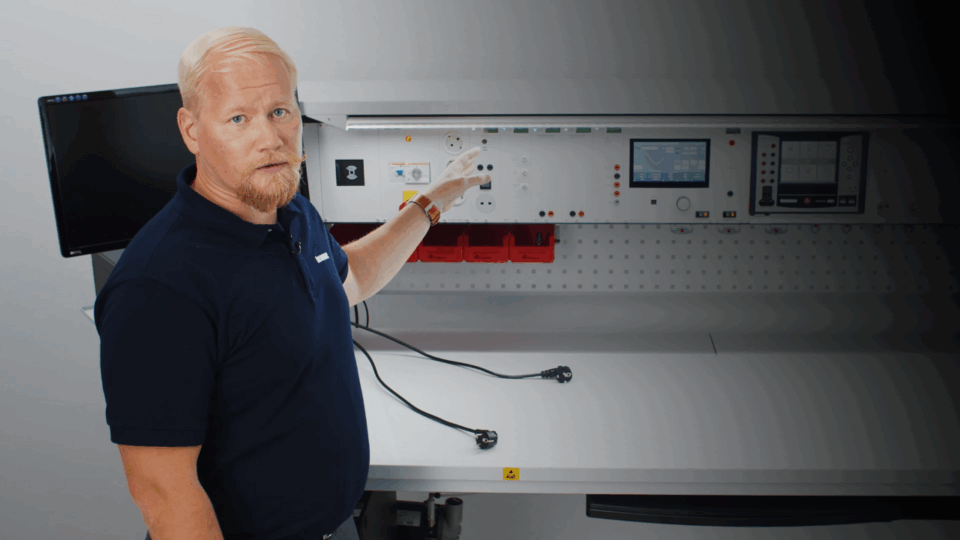

All components in the CENTRiCAL workshop calibration solution are protected against electrostatic discharge (ESD), so it is safe to handle ESD-sensitive items on the bench.

Ready calibrated

All the relevant modules in CENTRiCAL are calibrated before delivery and come with a calibration certificate, so you can start using the solution immediately.

Connect with calibration management software

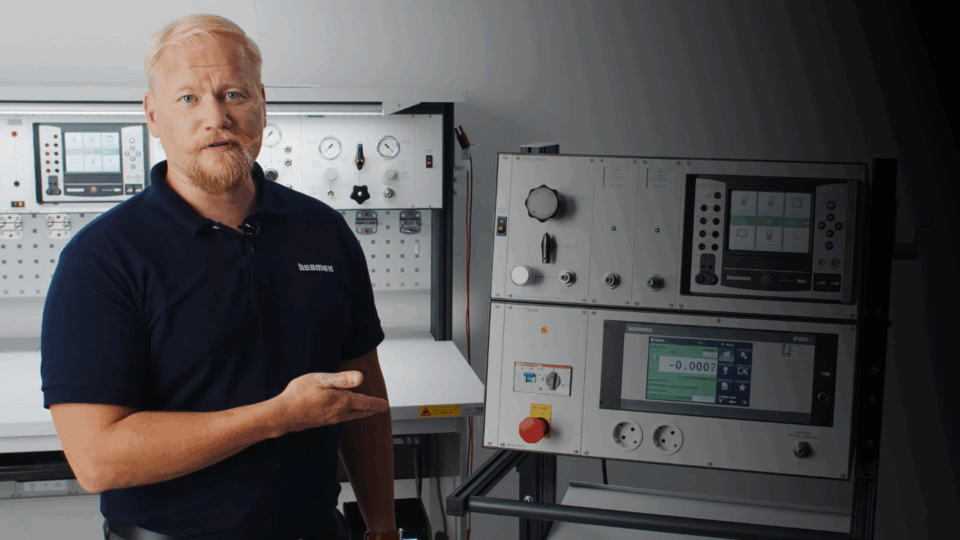

The MC6-WS Advanced Workshop Calibrator and Communicator is the heart of the CENTRiCAL workshop calibration Solution. It is a documenting calibrator that can connect with Beamex calibration management software, enabling a fully digital calibration data flow.

Find user manuals, brochures, declarations and more

Complementary products and accessories

A better way for workshop calibration

CENTRiCAL is a high-accuracy workshop calibration solution that provides accurate measurements and low calibration uncertainty. All relevant modules are delivered with a calibration certificate, ensuring your calibrations are traceable.

The MC6-WS workshop calibrator documents your calibrations without any manual typing or need for pen and paper, and automatically performs error calculation and pass/fail analysis.

CENTRiCAL is the most ergonomic solution for workshop calibration available today. All equipment is within easy reach, the bench height is electrically adjustable for maximum comfort, and the lighting ensures effective and safe working.

CENTRiCAL is available in various solutions: calibration bench, calibration trolley, and tabletop solution.

Modular versatility

The modular design makes CENTRiCAL versatile and easy to configure according to your needs, with the ability to add or replace modules as needed.

Available modules include the MC6-WS workshop calibrator, automatic and manual pressure generation modules, and pressure measurement modules.

Other options include mains (AC) power supplies, DC power supplies, multimeters, soldering stations, oscilloscopes, function generators, and much more.

You can further enhance your CENTRiCAL workshop calibration solution with a wide variety of accessories.

Let’s design your dream workshop!

Establishing a calibration workshop is a large project that can include many interrelated tasks an requires robust project management.

Our workshop calibration experts can give you advice, and we can help you define, deliver and adopt your unique solution, based on our vast experience with demanding customers globally.

Choose the right solution for you

CENTRiCAL bench

The Beamex CENTRiCAL calibration and test bench is available as a straight bench and as a corner bench version.

CENTRiCAL trolley

The Beamex CENTRiCAL trolley is equipped with wheels, an adjustable shelf, and a lockable drawer unit for storage.

CENTRiCAL tabletop solution

The Beamex CENTRiCAL tabletop case is a convenient solution if you already have tables in your workshop.

CENTRiCAL bench options

Motorized bench

CENTRiCAL M is a two-meter-long bench with electronically adjustable height.

Motorized corner bench

CENTRiCAL CM is a corner bench with electronically adjustable height.

Fixed height bench

CENTRiCAL F is a two-meter-long bench with fixed height.

Fixed height corner bench

CENTRiCAL CF is a corner bench with fixed height.

Digital data flow

The MC6-WS workshop calibrator is a documenting calibrator that captures data digitally and ensures a secure data flow between the calibrator and Beamex calibration management software.

You can use Beamex calibration management software to manage what, how, and when to calibrate, as well as to execute calibrations with the MC6-WS according to your pre-configured calibration procedure – even fully automatically.

This solution provides accurate measurements and traceable, reliable, and reusable data that can be used for analysis and reporting, as well as for generating calibration certificates.

Sustainable by design

Sustainability is a core component of the Beamex design philosophy. We want you to continue using your workshop calibration solution for many years. CENTRiCAL’s modular design means you can add or replace modules as your needs change, making it future-proof.

Our service plans, support, training, consultancy, and other expert services help you to get the most out of your CENTRiCAL workshop calibration solution throughout its entire lifecycle.

Firmware updates bring new features and performance improvements, and you can add new modules and software functionalities. Accessories are also quickly and easily available from the Beamex Webshop.