What is work order automation?

Work orders are typically created in a maintenance management system, often printed out and given to the person responsible for calibration. After calibrations are executed, the acknowledgment is commonly entered manually into the maintenance system.

When automated, work orders flow automatically and digitally from the maintenance management system to calibration software, which manages all the calibration details and execution. After the calibration, the calibration software automatically sends a digital acknowledgment to the maintenance management system.

With this automated work order flow, all manual paper-based steps are removed and the data flows digitally through the systems. This greatly improves efficiency and ensures high quality and the integrity of the calibration data.

Why integrate calibration and asset management systems?

Make better decisions

Shared data allows for deeper business integration with diverse processes. Centralize data to make it easier to retrieve, inspect and analyze.

Complete work orders faster

Integration minimizes data entry while automating data flow and saves time. Eliminate duplicate work through an automatic information transfer.

Improve data integrity

Cleanse and validate the information passing through the integration. Stop manually entering data into multiple systems. Audits are a breeze when you are confident in your data.

Easy integration with CMMS or ERP

Asset management integration with Beamex CMX Calibration Management Software can easily be accomplished with Computerized Maintenance Management System (CMMS) or Enterprise Resource Planning (ERP) systems, such as SAP, Maximo or Emerson’s AMS Device Manager, via a standardized, but configurable solution: Beamex Business Bridge.

Detailed calibration data and traceable calibration records are stored in CMX, while the plant hierarchy and instruments are created and maintained in the parent system. When calibration work has been performed, work order acknowledgments can be sent to the CMMS or ERP.

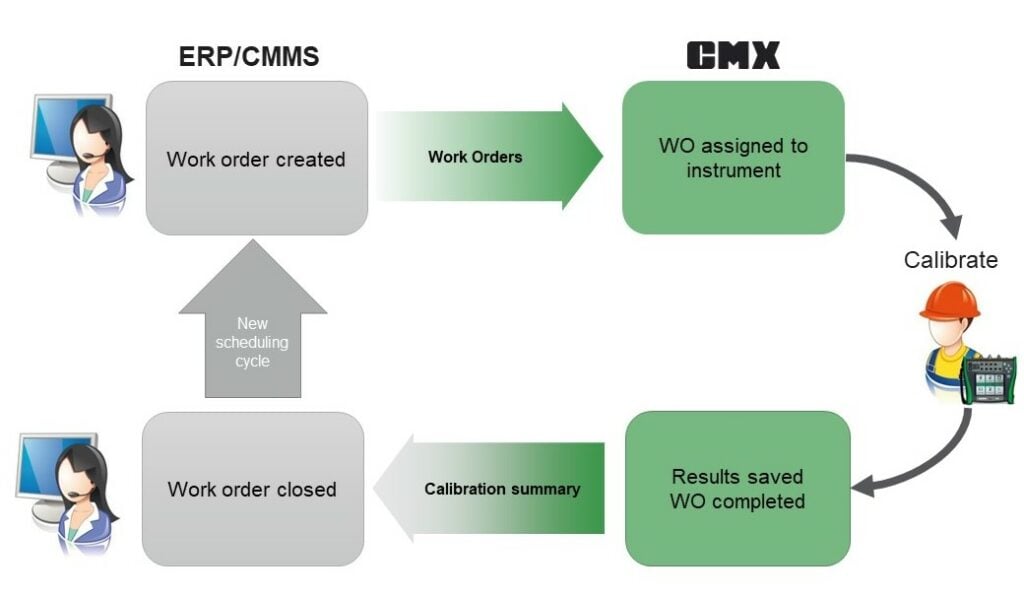

Work order handling process

In the CMMS or ERP system, calibrations are scheduled as part of the overall maintenance scheduling. Work orders (WO) are created for equipment due for calibration and then sent to Beamex CMX software using Beamex Business Bridge, with the calibration due date and WO number, as well as related information.

In CMX, the work order is assigned to instruments. The calibration due date and WO number are shown in CMX. Calibrations are executed according to the WO and calibration procedures. Calibration results are saved and the WO is completed in CMX.

A calibration summary is transferred back into the CMMS or ERP using Business Bridge and the WO is saved and closed in the CMMS/ERP.

What our customers say

Beamex calibration solutions

Calibration management

Discover how Beamex calibration software helps you digitalize and automate calibration processes.

Learn more >

Field calibration

Experience the Beamex portfolio of advanced field calibration technology.

Learn more >

Workshop calibration

Meet the Beamex range of industrial workshop calibration solutions.

Learn more >

Services

Get the most out of Beamex technology with expert services, and calibration and repair services.

Learn more >

Your partner for calibration excellence

We help our customers evaluate and select the right technologies and services to fit their unique operations. We understand regulations and industry-specific best practices. We will help you continuously analyze, improve, manage and execute.

Beamex has nearly 50 years of experience in developing and delivering calibration technology and expertise. Our experts around the world and our accredited calibration laboratories are here to support you.

Let our experts help you to find the best calibration solution for your needs.