Summary

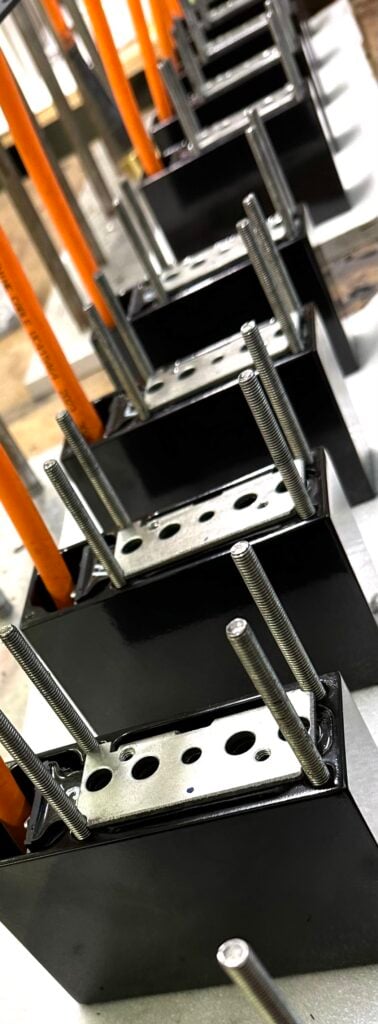

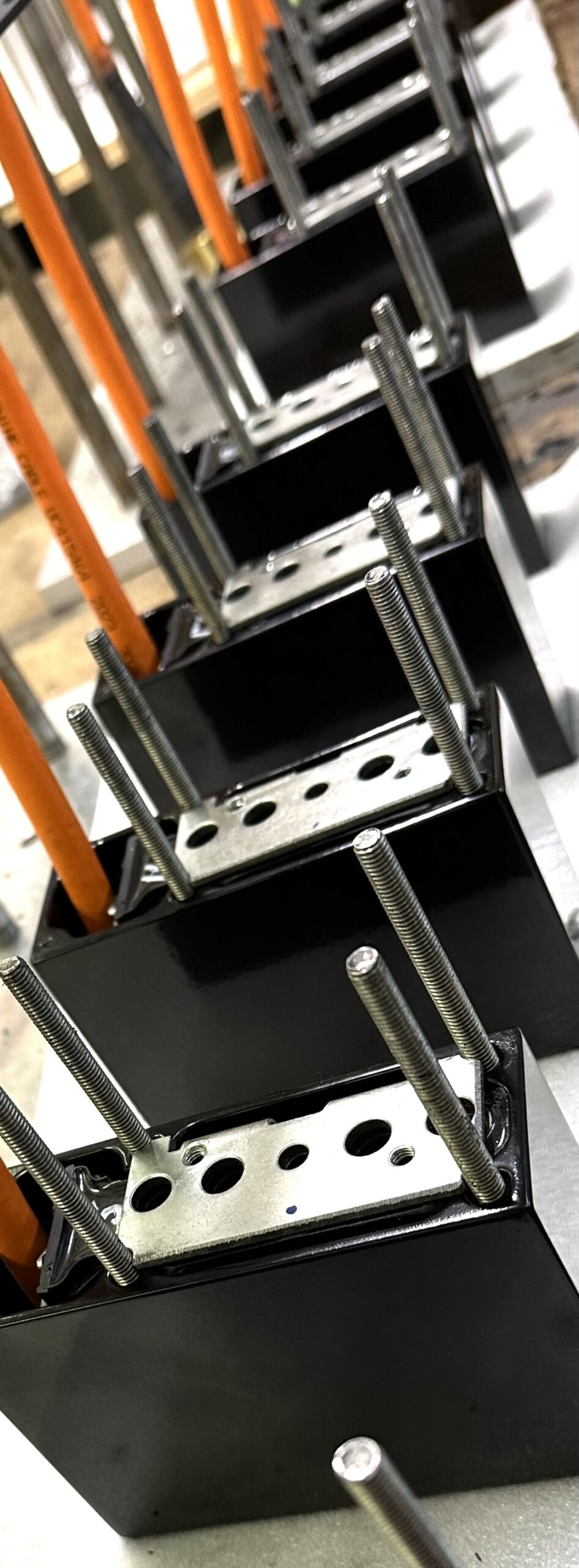

Paquin manufactures both standard and customized pressure and temperature sensors as well as a host of other sensor-based instrumentation. The company’s products are deployed in a wide variety of industries and applications. Before working with Beamex, Paquin had been relying on time-consuming calibration processes.

Calibration needed for critical components

Paquin has their headquarters and production facilities positioned in Cleveland, Ohio, as well as in West Union, South Carolina.

Legacy products produced are pressure and temperature sensors, ruggedized EX proof cable assemblies, actuators, valves and more. A long-term and strategic investment into the company will soon be publicly recognized as in 2024 Paquin will release their portfolio extension which includes flow, optical, level, ultrasonic, gas detection and additional sensor-based products. Beamex will play a critical role in the development, production, testing, and release of new products moving forward.

Beamex is the right choice

Beamex calibration equipment provides the necessary functionalities for Paquin to calibrate temperature and pressure within their production facilities. And taking it a step further, the Beamex MC6 calibrator will also allow Paquin to test and validate directly in the field if needed.

Paquin uses Beamex CMX Calibration Management Software to manage their instrumentation assets safely and to plan and execute calibrations efficiently. All calibration results are permanently stored to maintain a full calibration history, and data is easily available for analysis and reporting, as well as for generating calibration certificates.

Read the full case story

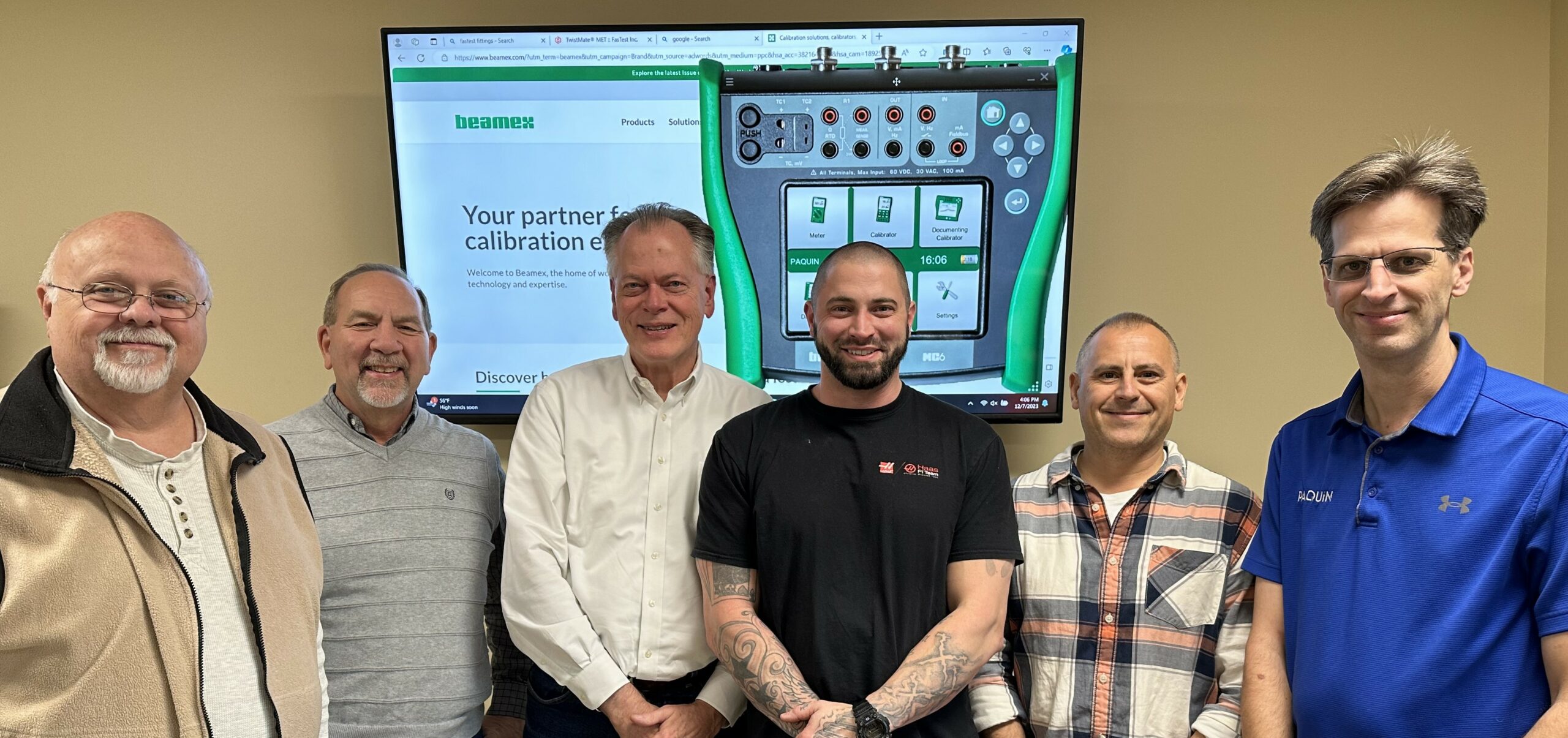

Close cooperation leads to better results

As part of the process of switching to Beamex calibrators and software, Beamex held demonstrations and practical training for Paquin employees on how to best use their new equipment.

Within two weeks of rolling out the new calibrator, Paquin found that the automated process saved six man-hours in just one calibration case. When savings like this are scaled up across the numerous calibrations Paquin does every year, using Beamex solutions will save a great amount of time while improving accuracy.

Paquin is now working with Beamex to expand the capabilities of their calibration system. The goal is to further improve the production process to make sure Paquin continues to produce the highest quality sensors possible.