Summary

The demand for cleaner batteries to provide sustainable power for a wide variety of applications is growing quickly. Swedish battery cell producer Northvolt is closing the loop on batteries with its Revolt Ett battery recycling plant, currently under construction in Skellefteå, northern Sweden. Many of the processes in this state-of-the-art facility will rely on Beamex hardware and software to

ensure accurate, traceable calibration.

A world-class facility to close the loop on batteries

Revolt Ett will house all the equipment and technology necessary to turn used batteries and battery production waste into raw materials. The plant will eventually recycle around 125,000 tons of battery materials per year, including production scrap from Northvolt Ett. When finished it will be the largest plant of its kind in the world, recovering lithium, nickel, manganese, and cobalt to support Northvolt Ett’s target of 50% of its raw material needs coming from recycling. As a trusted partner, Beamex has been part of Revolt Ett’s story right from the start.

Accurate, traceable calibration supporting a circular battery industry

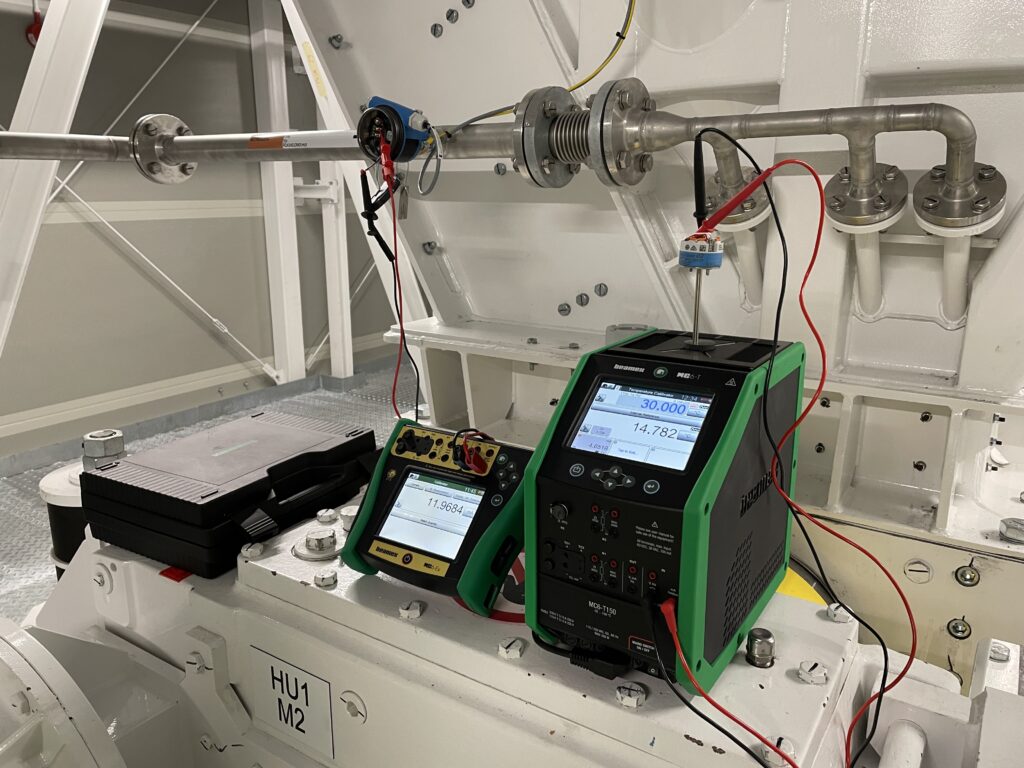

“The hydrometallurgical process we will use to extract metals from black mass – a powdered mixture of metals that are purified to recover the materials used to make fresh batteries – is dependent on temperature, among other variables,” explains Richard Porter, Instrumentation & Control System Supervisor. “As such, we need to be able to quickly and accurately calibrate a wide variety of equipment including resistance temperature detectors and thermocouples, as well as manage all the data that the calibration process generates.”

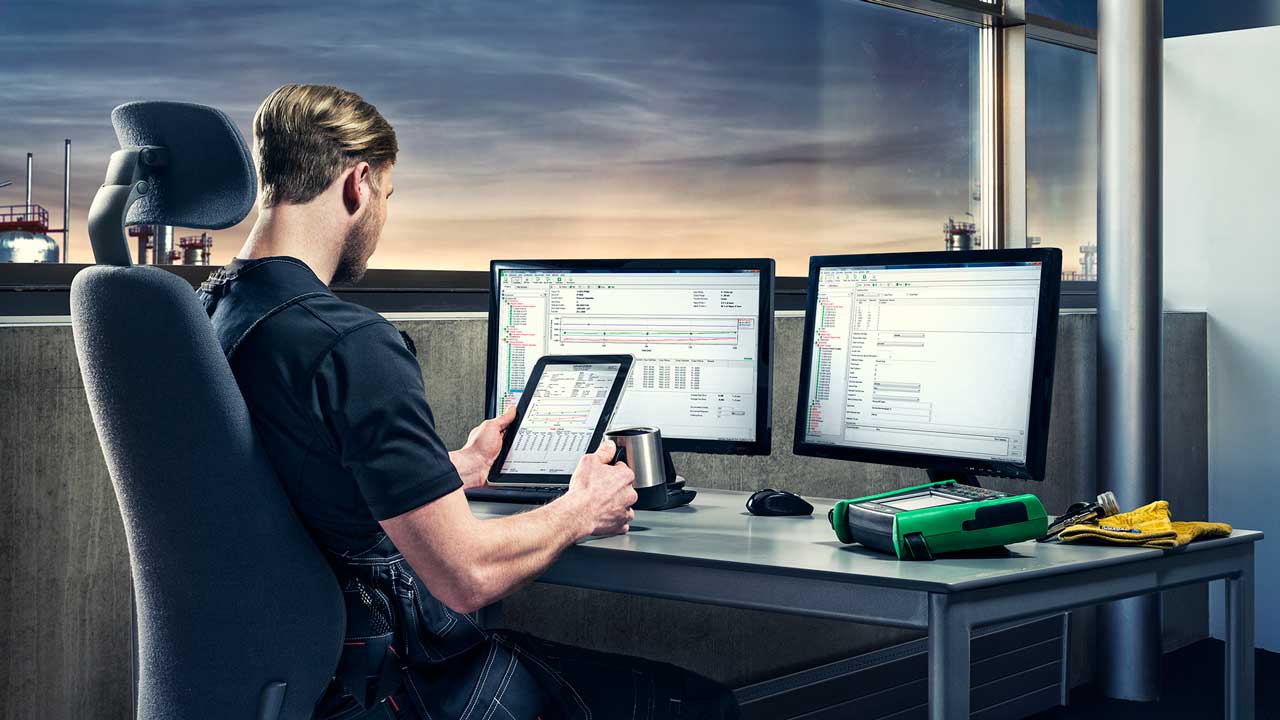

At Revolt Ett, Richard and his team will use several different models of the Beamex MC6, including an MC6-Ex Intrinsically Safe model for hazardous areas and an MC6-T150 with a temperature dry block alongside a variety of Beamex

calibration pumps. All calibration work at the plant will be

managed using Beamex CMX software.

Read the full Northvolt Ett case story

Global support and expertise with a local touch

In readying Revolt Ett for the start-up of production, Beamex’s

expertise has been just as important as the hardware and software they are providing to the site. Tom Sonntag, Head of Beamex Nordics, worked closely with Richard to scope out the required solutions and how best to roll them out at the site to ensure the best possible results.

“Tom came over to tour the site and provide valuable insights on what exactly we would need and the calibration strategies we could follow. This kind of hands-on, personal approach was extremely helpful for me,” highlights Richard. “Beyond that, once we had made the decision to go with Beamex the whole sales process was very easy, with everything going through one contact instead of multiple divisions. Plus, if I need technical support, parts, or even how-to videos for my team, they are all there in one place on the Beamex website or YouTube channel.”