Summary

The Beamex ecosystem plays a crucial role in testing and validation processes at REE Automotive. With Beamex hardware and software at their disposal, the company’s R&D staff are saving a huge amount of time and effort as they develop an innovative modular EV platform that is set to transform the e-mobility landscape.

A lasting first impression of Beamex

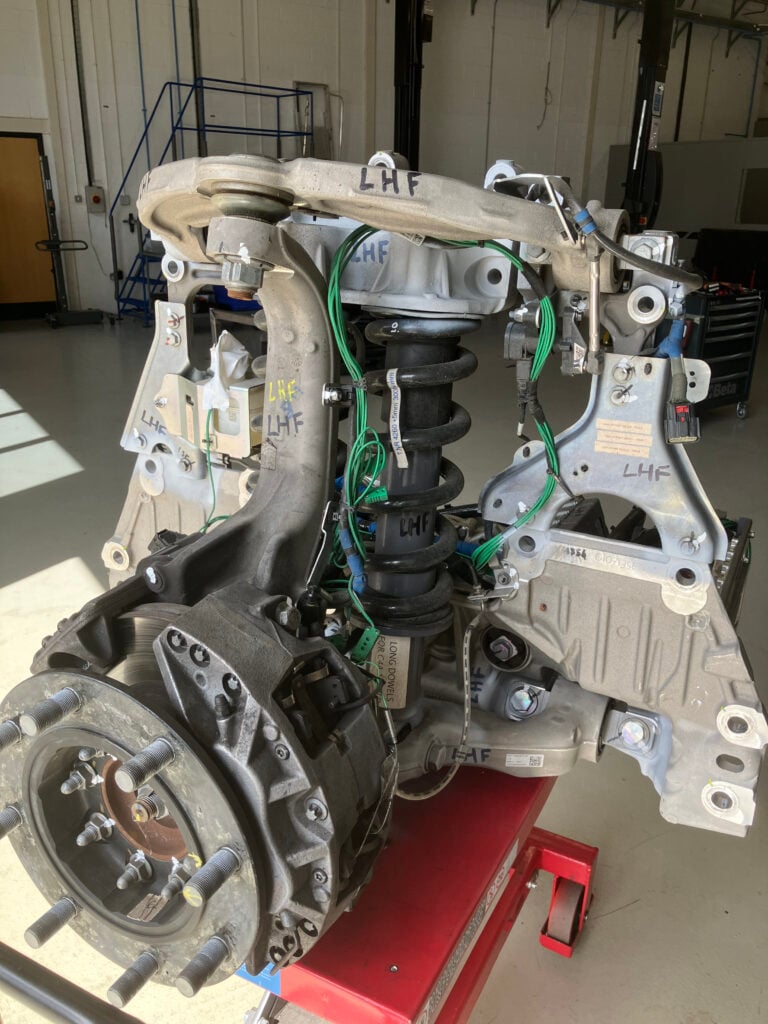

REE Automotive is developing a groundbreaking flat, scalable and modular next-generation EV platform that provides customers with unprecedented design freedom for EV and autonomous vehicle applications. Michael Denney, Test and Validation Engineer at REE, is the person responsible for making sure these critical devices are working properly and calibrated to the highest degree of accuracy.

Michael’s first encounters with Beamex came in his previous role at a UK-based startup that was developing an innovative new air compressor technology. The team was using a Beamex MC2 documenting process calibrator to calibrate pressure transducers and resistance temperature detectors (RTDs). “Beamex left a lasting impression because the equipment just worked day in, day out and had everything we needed in one unit,” Michael explains.

A calibration department in the palm of your hand

At REE, Michael and his manager were keen to make the calibration process as simple and cost effective as possible – without compromising on quality or accuracy. Given his previous positive experiences, Beamex was Michael’s first port of call, so he and Beamex’s Regional Sales Manager Aidan Farrelly sat down to map out what REE needed and what Beamex could do to meet those needs.

REE chose the Beamex MC6-T Multifunction Temperature Calibrator and Communicator along with Beamex LOGiCAL Calibration Management Software – a scalable cloud-based software-as-a-service solution. REE also received comprehensive classroom training on their new calibration ecosystem from a member of Beamex’s Calibration Solutions Group (CSG).

Read the full REE Automotive case story

Plug-and-play, paperless calibration

REE’s Beamex calibration solution means that the company no longer needs to buy ready-calibrated transducers. Michael estimates that the ability to perform and manage their own calibrations has already saved REE upwards of £20,000 – and a huge amount of time and effort. “The plug-and-play nature of the Beamex ecosystem is a big plus for us,” Michael explains. “We do our calibrations, the data gets automatically synced to LOGiCAL and it’s there for everyone to see. If we need data for an audit or reporting, for example, it just takes a few clicks to call up the relevant information.”

REE’s hardware is fully protected by a three-year Beamex Care Plan, covering regular recalibration and maintenance to keep their Beamex hardware reliable and accurate. “If we need support, Beamex are there for us immediately, and if they can’t give us an answer right away they’ll work on the issue until they find one,” Michael says. “The support has been first class, and their focus is always on making sure we can get the maximum value from our investment.”