Summary

Whitetower Energy’s team of field technicians rely on the Beamex calibration ecosystem to perform and manage calibration work across seven power plants around the UK. With technicians often working alone and between multiple sites, their Beamex hardware and software helps them execute jobs, manage data, and share information quickly and easily.

Bringing vital calibration work in house

Whitetower Energy is a small but vital part of the UK’s domestic power generation market. Its seven flexible gas- powered plants supply peaking power to balance the grid. The Peterborough plant, with a generation capacity of 293 MW, is home to the company’s central control room, from where all its UK sites are monitored. Whitetower Energy’s plants together contribute over 600 MW of power generation capacity to the UK grid.

“Before we came onboard with the Beamex ecosystem, we had no access or control over our own instrument database,” Lee Sigsworth, EC&I Technician for Northern England, explains. “After a calibration was done by the service company, we’d receive a certificate and that was it. With LOGiCAL we have full control over all our calibration data and can manage everything ourselves.”

Paperless calibration plus seamless data sharing

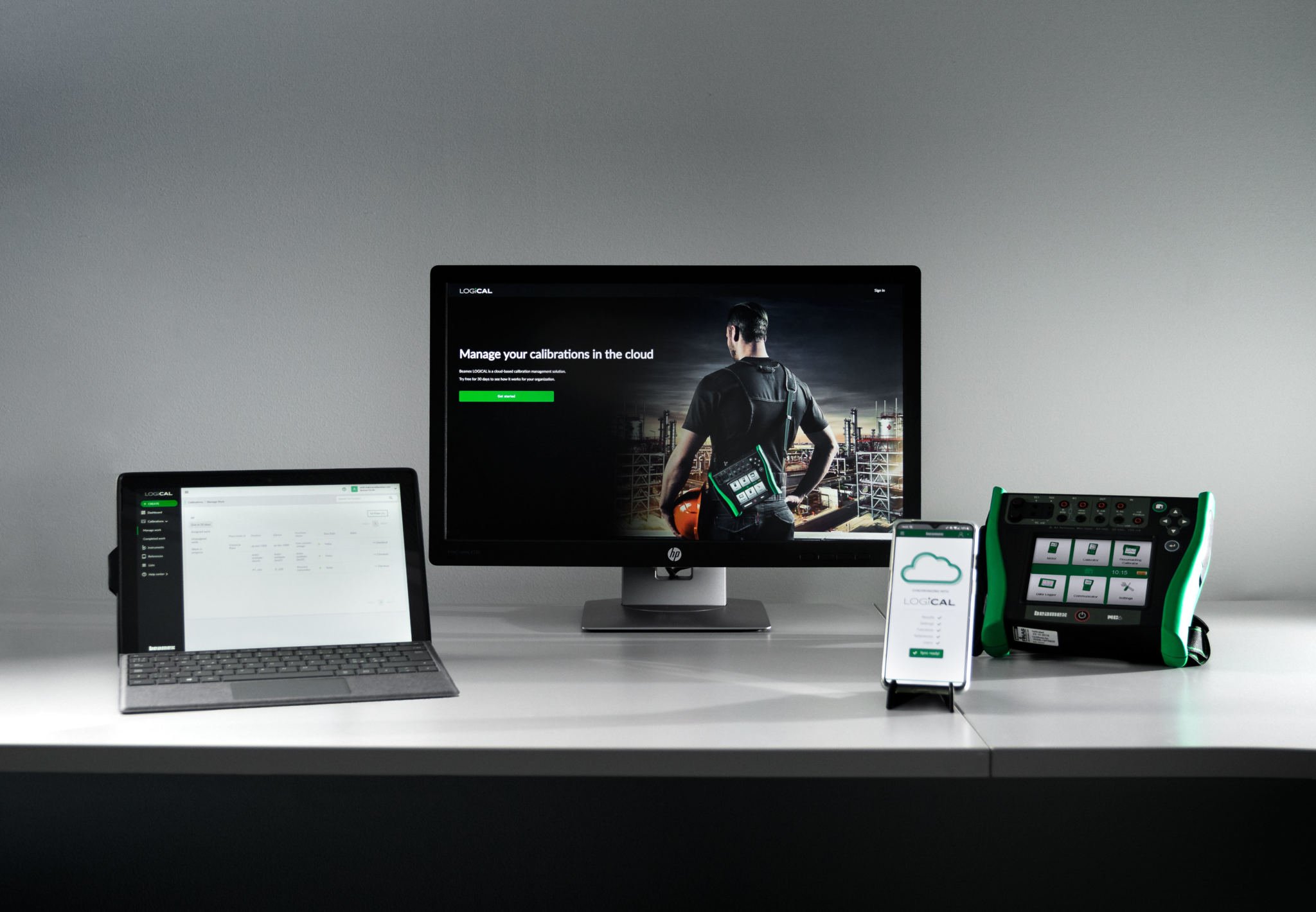

Today, each technician is equipped with a Beamex MC6 Advanced Field Calibrator and Communicator and a mobile device that connects to the cloud-based Beamex LOGiCAL Calibration Management Software. LOGiCAL puts easily scalable calibration management in the hands of Whitetower’s technicians, providing a cost-effective way to manage the instrumentation assets they are responsible for.

“The Beamex calibration ecosystem is just so easy to use,” Lee points out. “With the MC6 we can do temperature, pressure, and frequency calibrations all with a single unit. The calibrator guides you through the whole process right down to reminding you what cable to connect to which port, and once you’re done it syncs up with LOGiCAL, and everything is safely stored.”

Read the full Whitetower Energy case story

Holistic after-sales care reduces stress and effort

A great deal of the calibrations that Lee and his colleagues perform involve pressure, with the instruments they calibrate having to comply with the Health and Safety Executive’s Pressure Systems Safety Regulations (PSSR). The team uses a variety of Beamex manual calibration pumps to generate pressure, but the ace in their hand is the Beamex ePG Electric Pressure Pump and Controller. “I’m usually working alone, so with the ePG I can go away and check the data on an HMI screen somewhere else in the plant and leave the pump to maintain the correct pressure without worrying,” Lee says.

Whitetower benefits from the added peace of mind of a Beamex Care Plan for all four Beamex MC6 units. The plan covers annual recalibrations, repairs, and much more, and Lee is well aware of the value this brings. “We never have to worry about remembering when the units need recalibrating because Beamex contacts us well in advance to remind us,” he says.