Smart data analysis

Data is your most valuable asset. An optimal calibration solution captures data digitally at the measurement source and ensures secure data flow between products and systems.

A completely digital flow of traceable and reliable calibration data throughout your business improves efficiency, increases safety and ensures compliance.

Use your high-quality data to drive continuous improvement. Analyze trends, optimize maintenance procedures, increase traceability, adapt to change and deliver compliance. Data-enabled decision-making helps your whole team to work smarter.

The benefits of a digital flow of calibration data

Improve efficiency

Streamlined and automated calibration typically eliminates 50% of the time spent on the end-to-end calibration process. Minimize duplicate work with connected systems. Data-enabled decision-making helps your whole team to work smarter.

Increase safety

The secure flow of digital data minimizes human typing errors. High-quality calibration data is critical to ensure end-product quality. Identify problematic trends before they lead to failures and cut downtime. Rely on a calibration solution that evolves to meet your changing needs.

Ensure compliance

Guided calibration ensures a consistent and repeatable process every time. Deliver regulatory compliance with reliable and traceable data and enhance audit efficiency. Ensure calibration data integrity even when executing calibrations offline.

Experience a better way to digitalize with Beamex

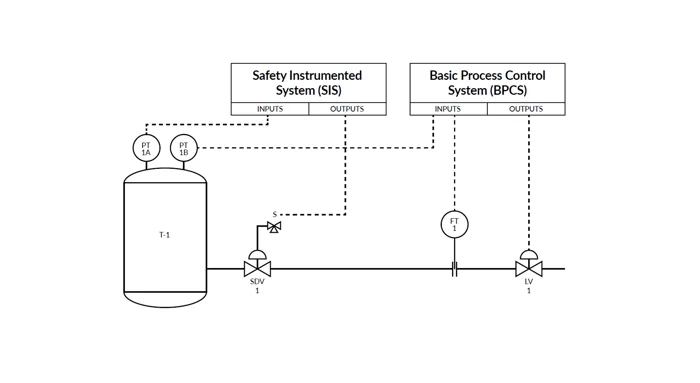

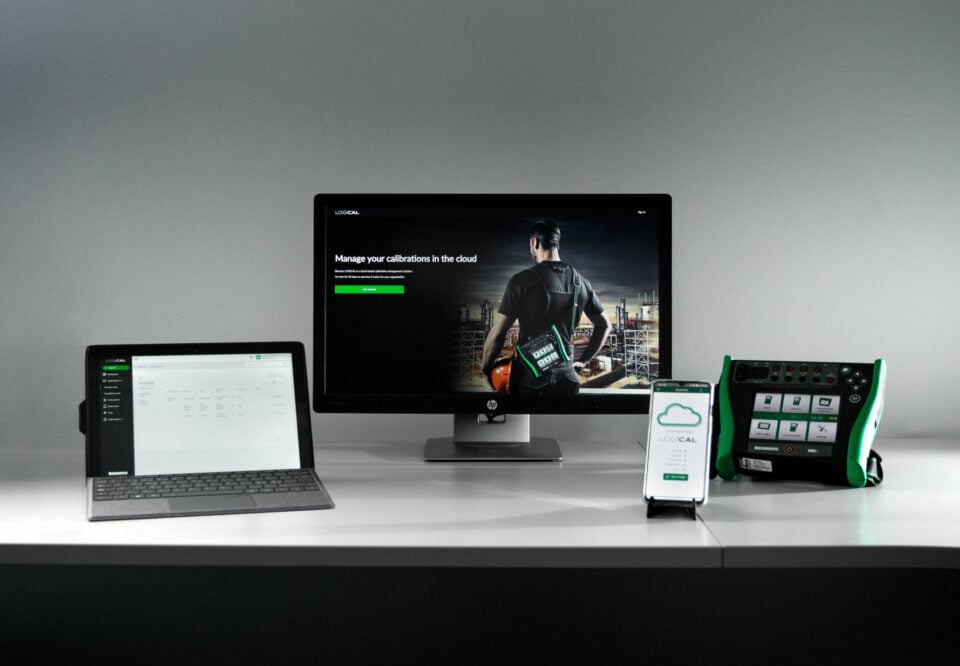

The core elements of Beamex calibration solutions are calibration management software and documenting field calibrators communicating seamlessly. The secure flow of digital data between products minimizes human typing errors and duplicate work.

Beamex LOGiCAL or CMX calibration management software can be used for managing instrumentation assets and their calibration procedures. The MC6 family of documenting calibrators or the bMobile Calibration Application can execute calibrations in the field and capture data at source. Beamex field solutions guide you step by step according to predefined procedures, ensuring consistency every time.

Calibration results are permanently stored in the calibration management software to give you a full calibration history. You get accurate measurements and traceable, reliable, and reusable data that can be used for analysis, reporting and calibration certificates.

With Beamex Business Bridge, CMX can be connected to leading maintenance management systems, such as SAP or IBM Maximo, so you can create a completely digital flow of calibration data throughout your business.

Related content

Why use a documenting calibrator? What are the benefits?

Documentation of the results is an essential element in every calibration. Documentation may be done manually using pen and paper or by inputting data into software. Using a documenting calibrator automates the entire documenting process.

Read article >

The evolution of calibration documentation

Today, we can send emails, text messages, and a variety of other digital communication around the world in a matter of seconds. Humans have evolved and documentation has evolved, and with it the way in which we manage calibration.

Read article >

How to avoid manual data entry errors?

Manual entry is still commonly used in industrial processes even though it is a slow and labor-intensive process with a high possibility of human error. In this article, we discuss industrial calibration processes and the manual data entry related to these processes.

Read article >

What our customers say

Your partner for calibration excellence

We help our customers evaluate and select the right technologies and services to fit their unique operations. We understand regulations and industry-specific best practices. We will help you continuously analyze, improve, manage and execute.

Beamex has over 50 years of experience in developing and delivering calibration technology and expertise. Our experts around the world and our accredited calibration laboratories are here to support you.

Beamex calibration solutions

Calibration management

Discover how Beamex calibration software helps you digitalize and automate calibration processes.

Learn more >

Field calibration

Experience the Beamex portfolio of advanced field calibration technology.

Learn more >

Workshop calibration

Meet the Beamex range of industrial workshop calibration solutions.

Learn more >

Services

Get the most out of Beamex technology with expert services, and calibration and repair services.

Learn more >

Let our experts help you to find the best calibration solution for your needs.