Efficiency, safety and sustainability

Maintaining high safety standards and ensuring regulatory compliance is the highest priority in the oil and gas industry, closely followed by optimizing efficiency. Doing so demands the right resources, knowledge, tools, and support.

A modern, automated calibration solution supports oil and gas industry professionals with regulatory compliance and adherence to documentation requirements while helping to maintain the highest level of safety.

Experience a better way to process valuable resources

Many of the world’s leading oil and gas companies rely on the Beamex calibration ecosystem. Our solutions are designed to help customers achieve their calibration-related goals in line with regulations, such as ATEX.

Our calibration solutions have been developed for more than 50 years by combining our own experience with feedback gained through close cooperation with oil and gas customers.

Industry trends and insights

What is operational excellence and how can calibration help achieve it?

In this article we discuss the history of the concept, what it means in practice, and how it applies to process industries. We’ll also set out how calibration can play a role in enabling operational excellence in your process industry plants

Read article >

Automating the calibration management ecosystem

While the pen might be mightier than the sword, in process industries pen-and-paper based calibration systems are a weak spot that is desperately in need of attention. Automating your calibration ecosystem saves time, reduces the risk of errors, and enables your organization to use calibration data for business benefits.

Read article >

Tackling the problem of human error in calibration data entry

Manual entry is still commonly used in industrial processes even though it is a slow and labor-intensive process with a high possibility of human error. In this article we discuss industrial calibration processes and the manual data entry related to these processes.

Read article >

Are you performing calibrations? Browse all our “how to” calibrate content and discover better ways to calibrate

Customer success stories

50%

Efficiency improvement of calibration procedures

Peñoles Quimica del Rey, Mexico

What our oil and gas customers say

Beamex calibration solutions

Calibration management

Discover how Beamex calibration software helps you digitalize and automate calibration processes.

Learn more >

Field calibration

Experience the Beamex portfolio of advanced field calibration technology.

Learn more >

Workshop calibration

Meet the Beamex range of industrial workshop calibration solutions.

Learn more >

Services

Get the most out of Beamex technology with expert services, and calibration and repair services.

Learn more >

Together we can find the ideal calibration solution for your operations

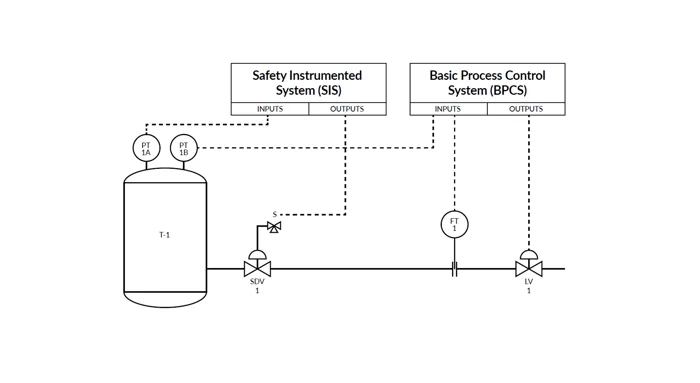

Gas transmission and distribution

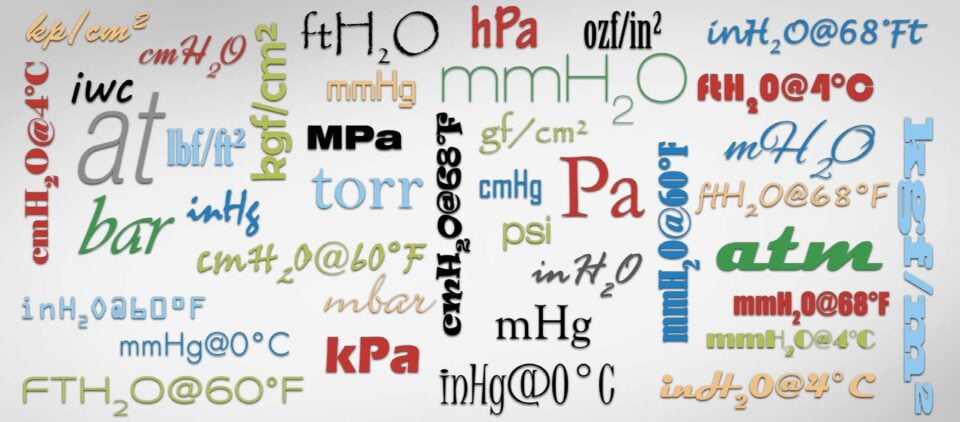

Using high-accuracy calibration equipment on gas flow instrumentation, like orifice plates, is essential to provide proper readings for custody transfer and to ensure regulatory compliance.

Beamex’s advanced, high-accuracy field calibrators and communicators are portable and suitable for a variety of differential pressure flow calibrations.

Ready for hazardous areas

We offer intrinsically safe field calibrators and communicators that can be used in hazardous Ex areas, where explosive gases may be present.

Our intrinsically safe calibrators are ATEX, IECEx, and North American certified for Zone 0, Zone 1, and Zone 2 (Division 1/2).