These are the challenges we see within maintenance operations

Regulatory

Compliance

Managing complex and stringent regulations can be challenging. However, with risks such as operational disruptions, fines, penalties, and environmental or safety concerns, ensuring compliance is more critical than ever.

Keep calm and prepare for more regulation >

Digital

Transformation

New technologies like IoT sensors, AI, and advanced analytics offer opportunities but also challenges. Beamex solutions simplify integration, reducing costs and complexity.

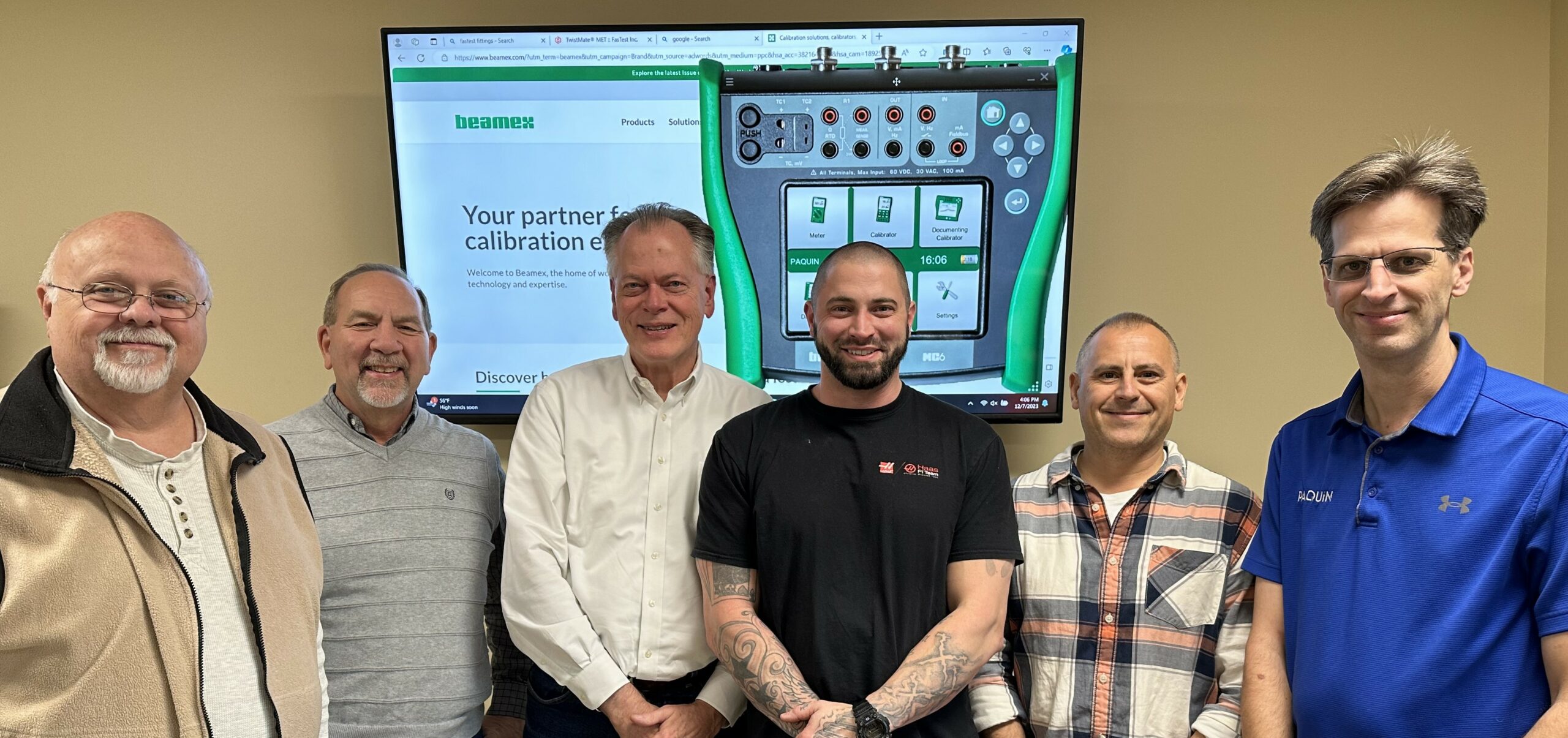

Why Paquin Sensors, US chose Beamex >

Knowledge Management

The process industry demands specialized skills and knowledge. Retaining skilled maintenance personnel is a challenge. As veteran employees retire, the shortage of trained workers grows more significant.

Capturing silent knowledge to train the next generation of workers >

Data

Analytics

Effective maintenance requires accurate data on equipment and maintenance history. Managing and analyzing this information can be overwhelming, especially when systems are not integrated or data is scattered across different platforms.

A visual overview of your calibration data >

At Beamex, we believe in a better way

A better way to calibrate

Intuitive user experiences and world-class customer care make calibration easy for everyone.

The Beamex ecosystem is continuously developing with state-of-the-art technologies. Expert services and support from our dedicated, highly knowledgeable team means a great experience every time.

The Beamex Ecosystem >

A better way to run your business

Make smarter decisions with the best lifecycle partner to automate and optimize processes, reduce error, and

mitigate risks.

We help you get more from your data, for example, by connecting calibration to other business processes, to increase plant availability and capacity.

Calibration software >

A better way for a sustainable future

Improve quality, auditability and deliver compliance with trustable and traceable measurement data.

Our high-quality, reliable solutions, combined with our world-leading expertise, help you future-proof operations and optimize processes to improve efficiency and reduce waste and emissions.

For a safer and less uncertain world >

Experience a better way to manage your calibrations

Accurate measurements, reliable data, and traceability help you to improve efficiency, ensure compliance, and increase safety in your operations.

Industry professionals require a modern, automated calibration solution that supports regulatory compliance and adherence to all documentation requirements while maintaining the highest level of safety.

We help our customers evaluate and select the right technologies and services for their unique operations. We understand industry-specific regulations and best practices, and our solutions evolve to meet changing business and regulatory environments. We will help you continuously analyze, improve, manage, and execute.

Customer success stories

50 %

Efficiency improvement of calibration procedures

Peñoles Quimica del Rey, Mexico

Calibration process savings calculator

This calculator focuses on your unique business environment and your potential OPEX savings from process optimization and digitalization, based on Beamex customer experiences around the world.

Discover how much you could save on operational costs in just a few clicks.

What our customers say

Many companies have found a better way with Beamex.

Beamex calibration solutions

Calibration management

Discover how Beamex calibration software helps you digitalize and automate calibration processes.

Learn more >

Field calibration

Experience the Beamex portfolio of advanced field calibration technology.

Learn more >

Workshop calibration

Meet the Beamex range of industrial workshop calibration solutions.

Learn more >

Services

Get the most out of Beamex technology with expert services, and calibration and repair services.

Learn more >

Join tens of thousands of industry leaders around the world for our monthly email digest: Calibration Tips

50 years of calibration expertise

Since 1975, Beamex has been a trusted partner for calibration excellence, helping customers to continuously improve efficiency, ensure compliance, and increase safety in their operations. With the Beamex ecosystem we set the industry standard with our way of working, our expertise and innovative calibration technologies that provide accurate measurements, reliable data, and traceability.

Industry trends and insights

What is operational excellence and how can calibration help achieve it?

In this article we discuss the history of the concept, what it means in practice, and how it applies to process industries. We’ll also set out how calibration can play a role in enabling operational excellence in your process industry plants.

Read article >

Automating the calibration

management ecosystem

While the pen might be mightier than the sword, in process industries pen-and-paper based calibration systems are a weak spot that is desperately in need of attention. Automating your calibration ecosystem saves time, reduces the risk of errors, and enables your organization to use calibration data for business benefits.

Read article >

Tackling the problem of human

error in calibration data entry

Manual entry is still commonly used in industrial processes even though it is a

slow and labor-intensive process with a high possibility of human error. In this article we discuss industrial calibration processes and the manual data entry related to these processes.

Read article >

Let our experts help you to find the best calibration solution for your needs.