How critical industries can benefit from partial IT/OT convergence

Antonio Matamala, Country Manager, Beamex Germany

There’s a growing need to enhance operational efficiency and leverage data for actionable insights in critical industries such as energy, pharmaceuticals, transportation and manufacturing. According to a McKinsey report, integrating physical and digital operations has the potential to create between USD 5.5 trillion and USD 12.6 trillion in global value by 2030.

This vision of efficiency focuses on merging Operational Technology (OT)—like PLCs, SCADA systems, and sensors managing “things” in a production plant—with Information Technology (IT), which processes data to support office-based business functions and inform “people”. While IT-OT integration offers transformative benefits, full convergence remains challenging in critical industries.

Challenges to full IT/OT convergence

As explored previously, security is a barrier to full IT/OT convergence in critical industries. For sectors handling essential infrastructure and high-stakes production environments, the danger of cyberattacks on OT systems is high. Connecting these historically isolated OT systems to broader IT networks can open them up to vulnerabilities, increasing the risk of disruption or sabotage.

Another obstacle to full convergence is the compatibility issues created by legacy infrastructure. Many OT systems in use today were developed decades ago, with stability and reliability as primary goals rather than connectivity or flexibility. These systems may struggle to interface with modern IT systems.

Upgrading or replacing legacy OT systems to enable integration can be complex and costly. Furthermore, these updates frequently require interruptions in production schedules, adding another layer of complexity for industries where continuous operation is crucial. In such cases, the drive toward convergence often comes up against the practicalities of maintaining uninterrupted operations with stable, proven systems.

Regulative requirements also limit the extent of IT/OT convergence in highly regulated sectors. Stringent compliance and documentation rules govern these industries, where changes to established processes or systems, especially in the pharmaceutical industry, require extensive review and validation.

These additional layers of regulatory oversight can make it even more difficult to bridge IT and OT without time-consuming adjustments.

Balancing efficiency and stability

Despite these challenges, companies in critical industries have found that they can still capture valuable benefits by adopting a partial approach to IT/OT convergence.

Instead of aiming for complete integration, organisations can look at specific opportunities where IT and OT alignment offers operational advantages without jeopardising safety or stability. For instance, one practical application is the addition of IoT sensors to monitor critical machinery.

By incorporating IoT monitoring into their systems, companies can collect data on specific operational parameters, such as vibration patterns on essential equipment, and use that data to anticipate maintenance needs before they escalate into costly failures.

In this case, regular calibration is essential to ensure the sensors provide accurate readings. A proper, seamless, integrated digital calibration process without media breaks to avoid manual errors helps maintain the integrity of the data, enabling more precise insights and decision-making. This approach to predictive maintenance, enabled by real-time monitoring, reduces downtime and boosts operational efficiency, all without disturbing the core OT systems.

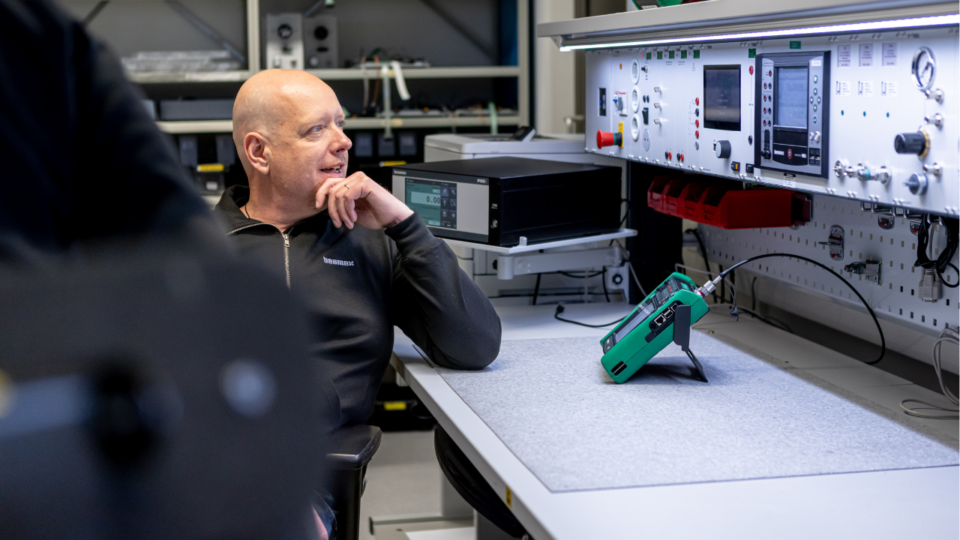

The stakes are even higher in highly regulated sectors such as pharmaceuticals. Calibration data, for instance, plays a critical role in audits. A mistake in calibration can have far-reaching consequences, such as regulatory fines, the need to withdraw a product from the market or even the loss of operating licenses. The use of documenting calibrators that transfer calibration data directly to calibration management software has proven to be a highly effective method for ensuring a seamless audit process.

By operating at the OT level and interfacing directly with sensors, Beamex calibrators bridge the gap with IT-level Beamex calibration management software, which manages and analyses the collected calibration data. This integration ensures smooth plant operations while leveraging IT systems to inform personnel about the performance and efficiency of production processes. In fact, the Beamex Calibration Ecosystem spans the entire IT-OT spectrum, providing a secure solution that leverages the benefits of IT without compromising the integrity and stability of OT systems.

This example underscores the importance of cautious, well-planned IT/OT integration, ensuring that any data involved is accurate and compliant with strict regulatory standards.

In this context, selective integration becomes critical. While real-time integration, like connecting SCADA systems to ERP software to trigger purchases, might be ideal, it’s not always practical. Instead, a step-by-step approach, focusing on areas where IT/OT convergence can add tangible value, helps companies stay on track with their operational and compliance goals.

A strategic path forward

Some organisations implement buffer zones between the two environments to facilitate smoother IT/OT convergence. These zones enable secure data flow without exposing OT systems to potential vulnerabilities. Specialised gateways help bridge IT and OT systems, allowing data sharing while safeguarding critical OT assets and enabling valuable insights.

Significant benefits arise when OT-generated calibration data is integrated with IT systems in a typical business setting, enabling actionable insights and driving operational improvements. For instance, one of our clients calculated savings of well over EUR 2 million annually by extending sensor calibration intervals, which reduces the need for labour-intensive maintenance tasks.

These decisions demand a robust data foundation, as the risks of operating machines with infrequently calibrated sensors can be significant. Comprehensive data analysis provides a reliable basis for maintaining compliance, successfully passing rigorous internal or external audits, and reducing operational costs through optimised calibration strategies. This example shows a business-driven motive for IT/OT convergence—driven by the goal of cost savings, operational excellence and doing more with fewer resources.

In fact, beyond the immediate gains in uptime and security, partial convergence also unlocks business intelligence and operational insights by making selective OT data available to IT applications while maintaining clear boundaries and separation between the two environments. Manufacturing Execution Systems (MES) offer an example of how this integration can drive valuable insights.

By aggregating data from shop-floor devices, these systems create a bridge between operational data and business insights, empowering companies to refine workflows, improve scheduling and manage inventory more effectively. Here, too, companies can improve operational efficiency without exposing their entire OT ecosystem to IT environments, maintaining stability while gaining visibility.

As critical industries continue to seek methods for operational excellence, partial convergence emerges as a practical and forward-looking approach that respects the unique demands and constraints of their high-stakes environments. A business-driven approach that prioritises efficiency, cost savings and regulatory compliance while leveraging IT/OT integration securely and gradually is a crucial strategy for staying competitive and resilient in the marketplace.

You might also find interesting

For a safer and less uncertain world

Welcome to our series of topical articles where we discuss the impact that accurate measurement and calibration has on the world and our everyday lives.