A better way for workshop calibration

The Beamex MC6-WS is a high-accuracy, panel-mounted workshop calibrator and communicator, that combines advanced functionality with ease-of-use. It offers calibration capabilities for pressure, temperature, and various electrical signals, and can be used as multi-bus communicator for fieldbus instruments. Calibrations can be executed automatically, digitally capturing data at source and storing calibration results securely.

The MC6-WS is the heart of the Beamex CENTRiCAL NA workshop calibration solution.

A versatile workshop calibrator

The MC6-WS is a versatile panel-mounted calibrator and is the heart of the Beamex CENTRiCAL workshop calibration solution.

High accuracy

The MC6-WS is a reliable and stable calibrator with unmatched accuracy. Each MC6 is delivered with a traceable, accredited calibration certificate as standard as proof of its accuracy.

Advanced functionality

The MC6-WS is a multifunction calibrator and multi-bus communicator with calibration capabilities for pressure, temperature, and various electrical signals. The MC6-WS offers a lot of useful features that support your calibration process and it can even perform fully automatic calibrations. It also offers versatile functionalities beyond traditional calibration applications.

Enhanced usability

The MC6-WS offers several intuitive user interface modes that are optimized for different use cases and available in multiple languages. The calibrator guides you step-by-step in your calibration work.

Field communicator

The MC6-WS contains a multi-bus field communicator for HART, FOUNDATION Fieldbus, and Profibus PA protocols to calibrate, configure, and trim your smart instruments. All three protocols can be enabled simultaneously.

Digital data flow

The MC6-WS is a documenting calibrator that communicates with Beamex calibration management software, enabling a fully digitalized calibration process.

Measurement, generation and simulation capabilities

- Pressure measurement (panel mounted/external pressure modules)

- Voltage measurement (±1 V and −1…60 VDC)

- Current measurement (±100 mA) (internal or external supply)

- Frequency measurement (0…50 kHz)

- Pulse counting (0…10 Mpulse)

- Switch state sensing (dry/wet switch)

- Built-in 24 VDC loop supply (low impedance, HART impedance or FF/PA impedance)

- Voltage generation ( ±1 V and −3…24 VDC)

- Current generation (0…55 mA) (active/passive, i.e. Internal or external supply)

- Resistance measurement, two simultaneous channels (0…4 kΩ)

- Resistance simulation (0…4 kΩ)

- RTD measurement, two simultaneous channels

- RTD simulation

- TC measurement, two simultaneous channels (universal connector/mini-plug)

- TC simulation

- Frequency generation (0…50 kHz)

- Pulse queue generation (0…10 Mpulse)

- HART communicator

- FOUNDATION Fieldbus communicator

- Profibus PA communicator

(Some functions are optional)

GENERAL SPECIFICATIONS

| FEATURE | VALUE |

|---|---|

| Display | 5.7” Diagonal 640 x 480 TFT LCD module |

| Touch panel | 5-wire resistive touch screen |

| Keyboard | Membrane keyboard |

| Backlight | LED backlight, adjustable brightness |

| Weight | 5.5. kg (12 lb) |

| Dimensions | 250 mm x 200 mm x 305 mm (W x H x D) (9.84 in x 7.87 in x 12.01 in) |

| Operating temperature | −10…45 °C (14…113 °F) |

| Storage temperature | −20…60 °C (−4…140 °F) |

| Specifications valid | −10…45 °C, unless other mentioned |

| Humidity | 0…80% R.H. non condensing |

| Warmup time | Specifications valid after a 5 minute warmup period. |

| Max. input voltage | 30 V AC, 60 V DC |

| Display update rate | 3 readings/second |

| Safety | Directive 2014/35/EU, EN 61010-1:2010 + A1:2019 + AC:2019-04 |

| EMC | Directive 2014/30/EU, EN IEC 61326-1:2021 |

| RoHS compliance | ROHS II Directive 2011/65/EU, EN IEC 63000:2018 |

| Vibration | IEC 60068-2-64. Random, 2 g, 5…500 Hz |

| Max altitude | 3,000 m (9,842 ft) |

| Warranty | 3 years |

Find user manuals, brochures, declarations and more:

Complementary products and accessories for Beamex MC6-WS

A better way for workshop calibration

The MC6-WS is a high-accuracy calibrator that ensures accurate measurements and low calibration uncertainty. Each MC6-WS is calibrated in the Beamex Accredited Calibration Laboratory, ensuring your workshop calibrations are traceable.

It documents all your calibrations without any manual typing or use of pen and paper and automatically performs error calculation and pass/fail analysis.

Use the MC6-WS together with a Beamex POC8 pressure controller, Beamex ePG electric pressure pump or supported temperature dry blocks for fully automatic pressure and temperature calibrations.

The MC6-WS is the main calibrator in the Beamex CENTRiCAL NA workshop calibration solution.

Digital data flow

The MC6-WS is a documenting calibrator that digitally captures data at source and ensures a secure data flow between the calibrator and Beamex LOGiCAL or CMX calibration management software.

The seamless data flow between products delivers efficiency and high-quality data.

Use calibration management software to manage what, how, and when to calibrate, and execute the calibration with the MC6-WS according to your pre-configured calibration procedure – even fully automatically. Maintain the full calibration history in LOGiCAL or CMX.

This solution provides accurate measurements and traceable, reliable, and reusable data that can be used for analysis, reporting and calibration certificates.

As a communicator, it enables digital communication with smart field instruments.

Sustainable by design

Sustainability is a core component of the Beamex design philosophy. We want you to continue using your calibrators for many years, so they are designed to have a long service life and to be as easy as possible to repair, maintain, and upgrade.

Our world-leading experts can help you to get the most out of your calibrator throughout its entire lifecycle with calibration and repair services, training, and calibration consultancy.

To meet your changing needs, our products are constantly evolving. Firmware updates provide new features or performance improvements, and you can also upgrade your existing products with new modules or software functionalities. Accessories are quickly and easily available in the Beamex webshop.

Learn more about sustainable by design.

User interface modes

A calibrator should have advanced functionality yet remain easy to use, which is why the MC6-WS offers several user interface modes that are optimized for different use cases. For example, if you only want to measure something quickly and easily, use the Meter mode. If you want to perform automatic calibrations, use the Documenting Calibrator mode.

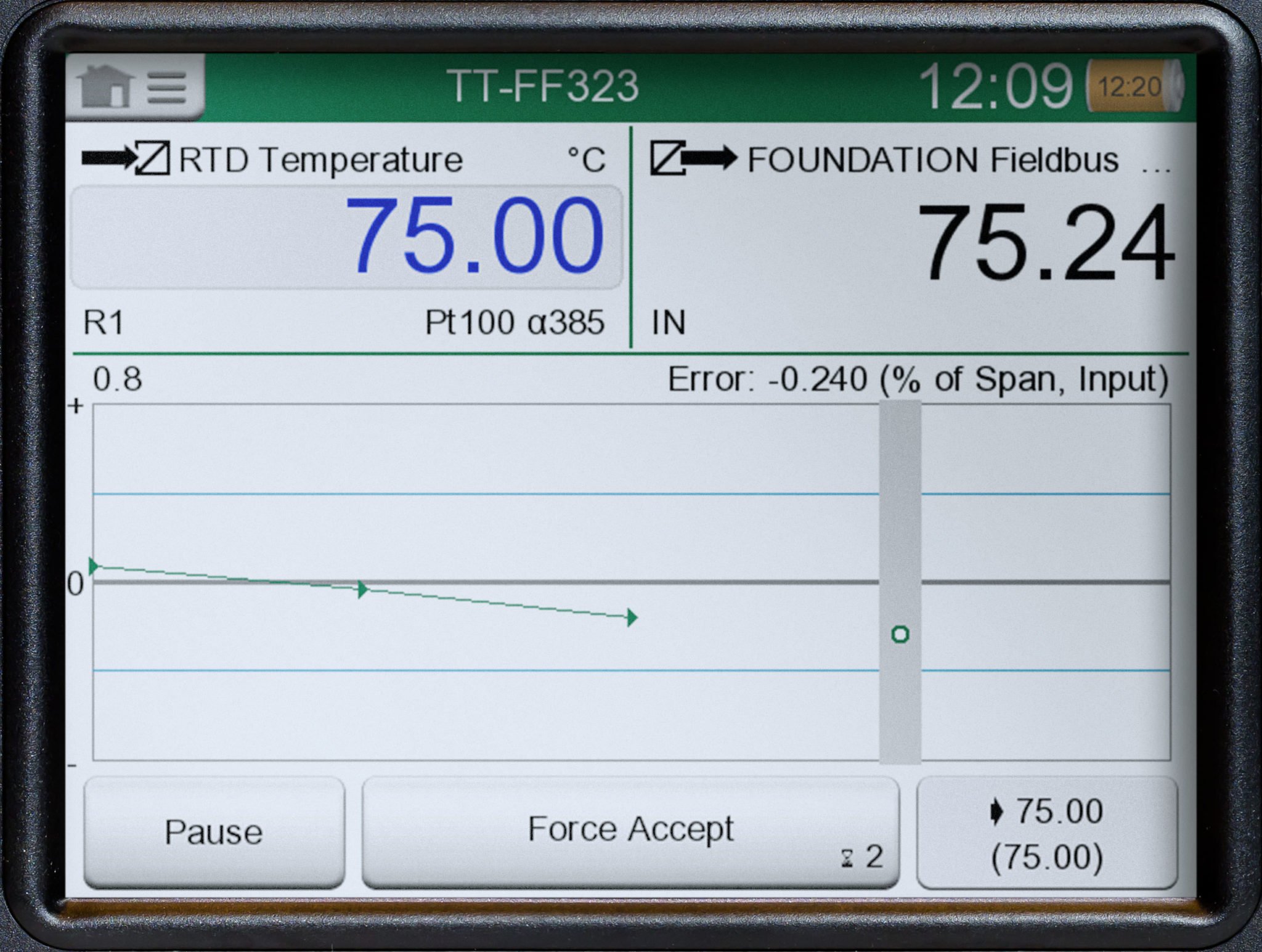

Documenting Calibrator

The Documenting Calibrator mode is designed for the documented and automated calibration of process instruments.

In today’s process plants, calibrations often have to be documented – without a documenting calibrator, this must be done manually, which takes a lot of precious time and is prone to errors.

With the Documenting Calibrator mode, the calibration process is guided, and the calibrator can automatically set the calibration points and document the results.

The Documenting Calibrator mode also works together with calibration management software.

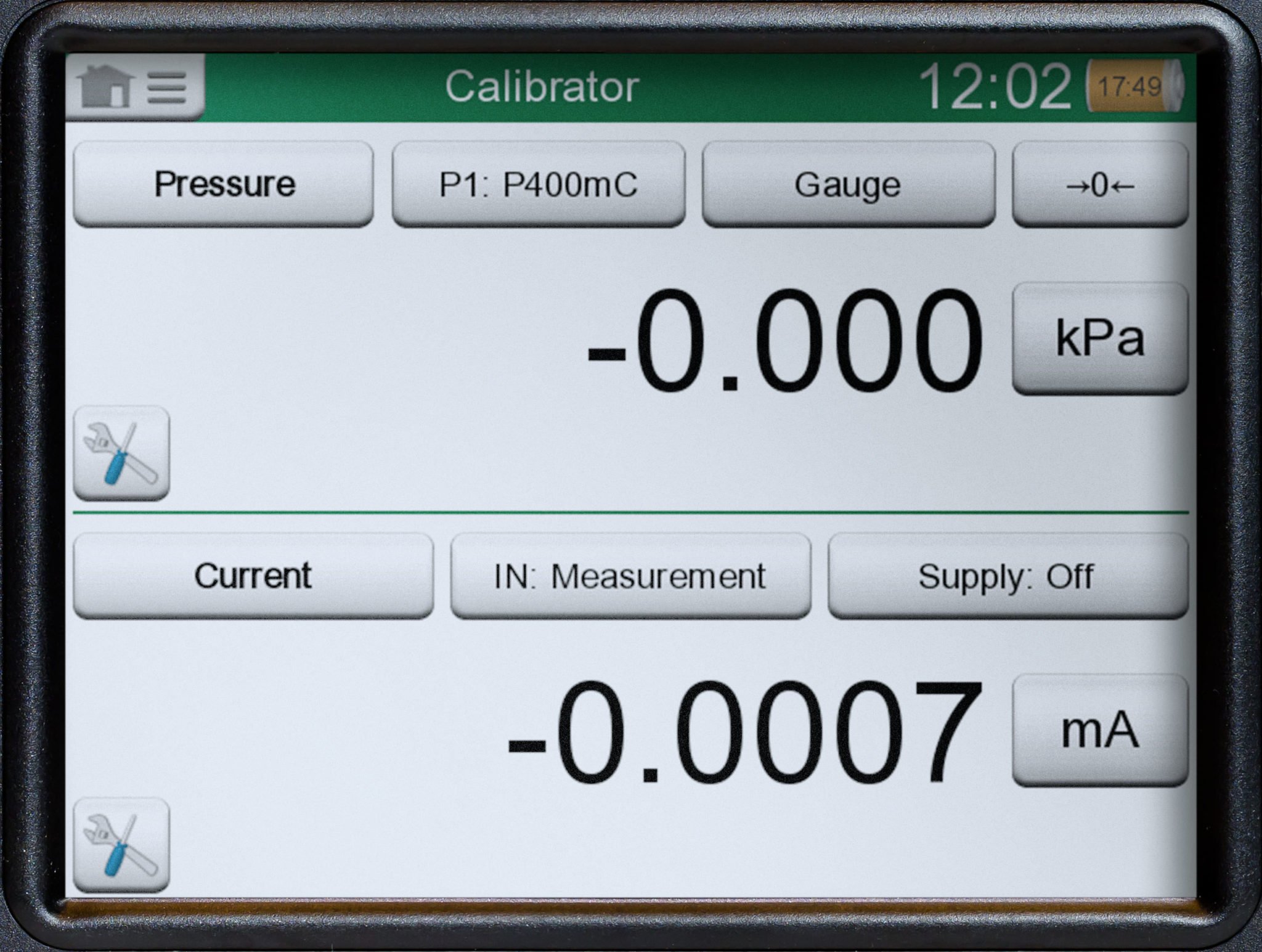

Calibrator

The Calibrator mode is designed for calibrating various process instruments. It enables you to measure or simulate two signals at a time.

Often you need to check and calibrate process instruments, which typically have an input and an output. This means you either need two devices, or a single device capable of doing two things simultaneously.

The Calibrator mode is optimized for this type of use.

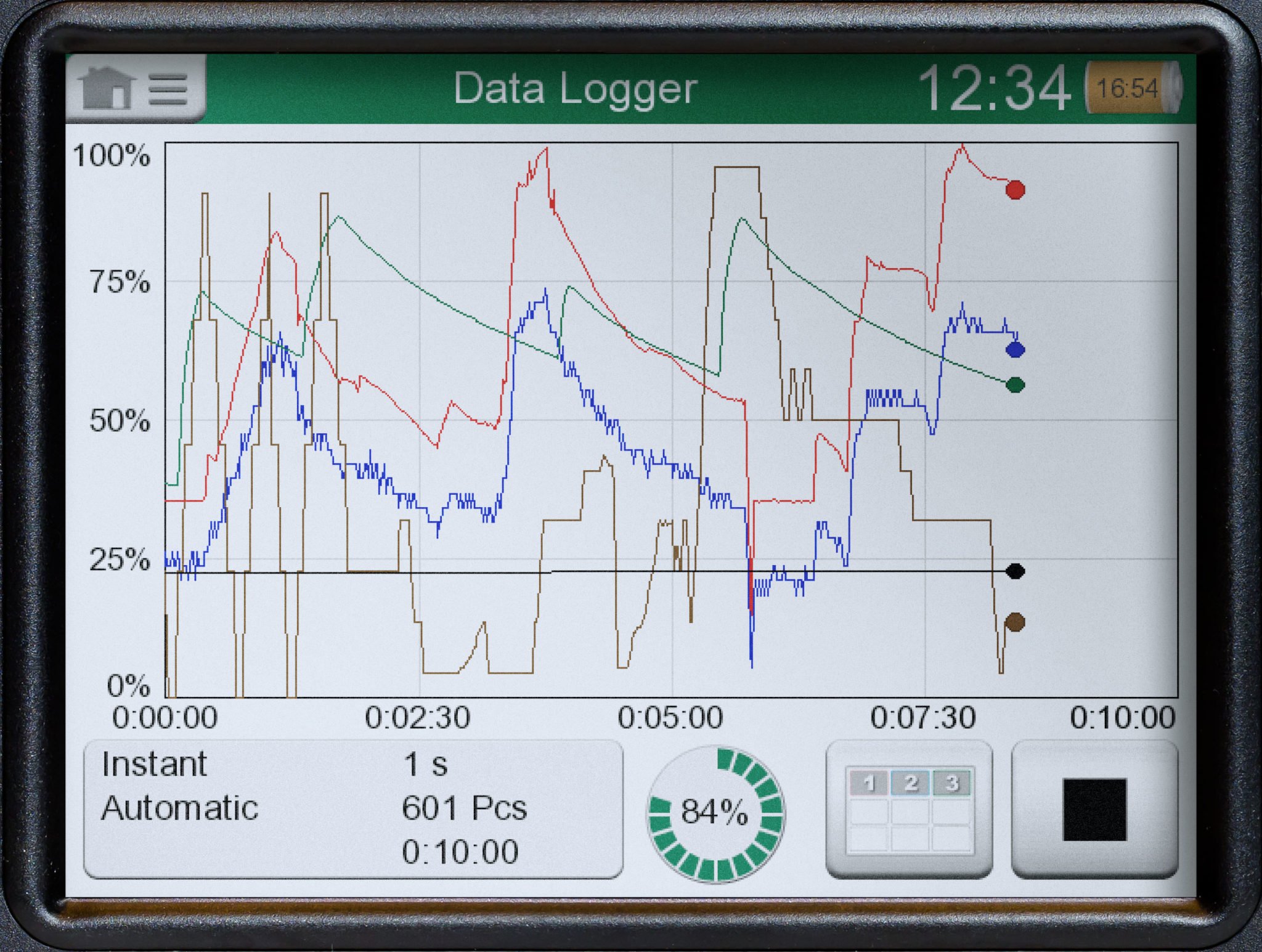

Data Logger

The Data Logger is designed for logging up to nine measurements simultaneously.

Often in industry, there is a need to measure signals for a certain period and to save the results for later analysis. This may be related to troubleshooting, surveillance, or calibration.

The data log results can be displayed in numerical or graphical view, and results can be transferred to a PC for further analysis.

The Data Logger mode is optimized for this type of use.

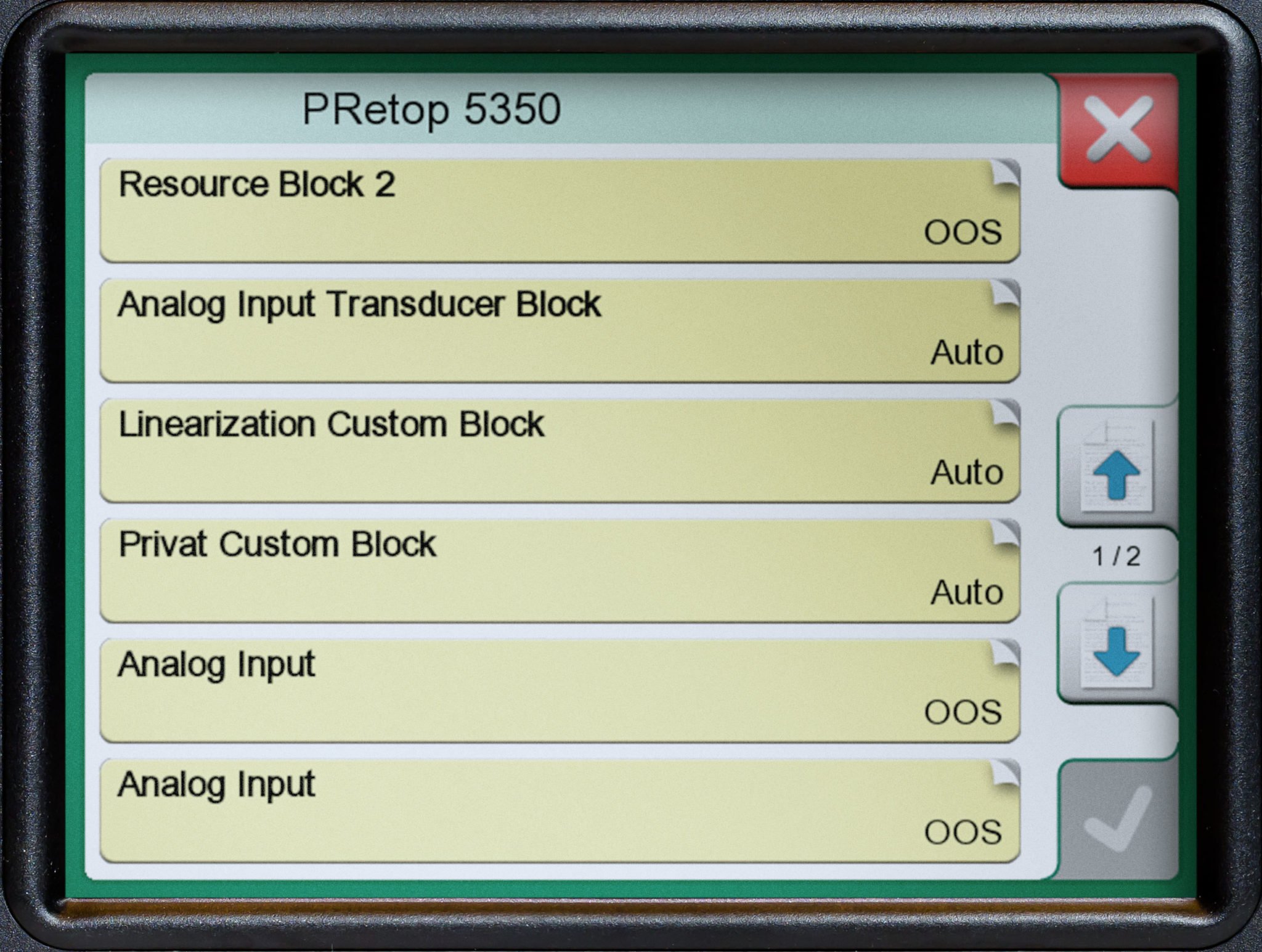

Communicator

The Communicator mode is designed to communicate with fieldbus instruments.

In today’s process plants, smart instrumentation is being used to an increasing degree, so engineers need to use communicators or configuration software. Most of this instrumentation is HART, FOUNDATION Fieldbus, or Profibus PA.

The Communicator mode is optimized for communicator use to calibrate, configure, and trim your smart instruments.

Meter

The Meter mode is designed for quick and easy signal measurement.

Some multifunction calibrators are slow and difficult to use, so a simple multi-meter is used for quick measurements.

The Meter mode is optimized for simple and easy metering, meaning one calibrator can be used for all measurements.

Related products and services

Workshop calibration

The Beamex CENTRiCAL NA offers a versatile workshop calibration solution.

Learn more >

Calibration software

Calibration management software enables automated digital data flow, when used together with Beamex documenting calibrators.

Learn more >

Pressure controller

The Beamex POC8 automatic pressure controller offers an automatic solution for pressure calibration.

Learn more >

Services

Keep your calibrator operating and traceable through its life-cycle with calibration and service plans.

Learn more >