Talk to our experts to find the best solution for your needs.

Beamex MC6-T Temperature Calibrator

The Beamex MC6-T is an extremely versatile portable temperature calibration system. It combines a state-of-the-art temperature dry-block with Beamex MC6 multifunction process calibrator and communicator technology.

Beamex RPRT Reference Temperature Sensors

Beamex RPRT reference sensors are high-accuracy reference temperature sensors with built-in memory for storing the individual probe coefficients. It boasts excellent quality and long-term stability.

Beamex RPRT probes can be used with Beamex temperature calibrators and the MC6 family calibrators.

Beamex MC6

The Beamex MC6 is an advanced field calibrator that offers a lot of functionality for temperature calibration, such as RTD and thermocouple measurement and simulation, with dual measurement channels for both.

It can also control supported temperature blocks, enabling a fully automatic calibration of various temperature instruments.

Beamex MC6-Ex

The MC6-Ex is an intrinsically-safe calibrator that offers a lot of functionality for temperature calibration, such as RTD and thermocouple measurement and simulation, with dual measurement channels for both.

It can also control supported temperature blocks, enabling a fully automatic calibration of various temperature instruments.

Beamex MC6-WS

The MC6-WS is a panel-mounted version of the portable MC6 calibrator, offering the same functionality for temperature calibrations.

The MC6 Advance Workshop Calibrator and Communicator can be installed in the Beamex CENTRICAL NA Calibration Bench.

Beamex CENTRICAL NA Calibration Bench

The CENTRICAL NA Calibration Bench is a modular test and calibration bench for workshops and laboratories.

It can be equipped with the MC6-WS calibrator and also with modules dedicated for temperature calibrations.

Questions and answers

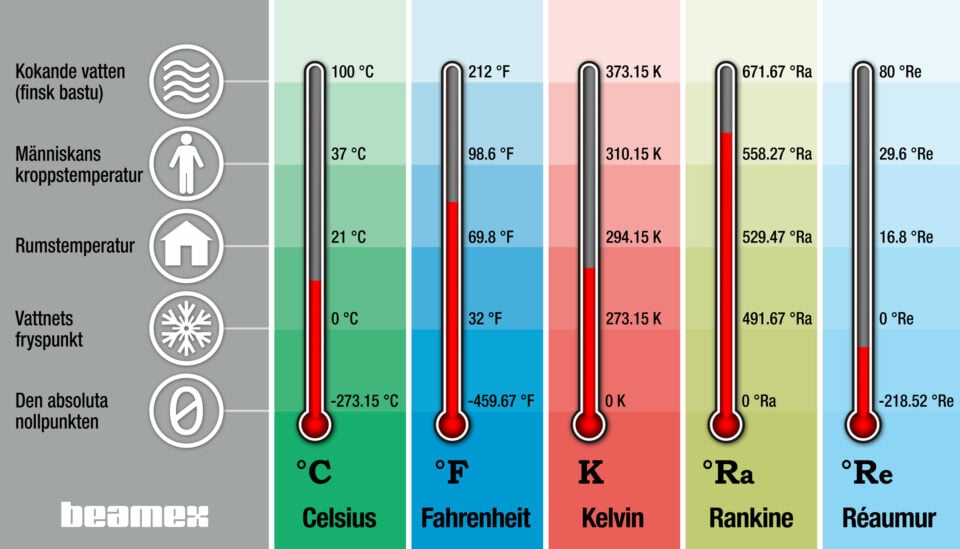

A temperature calibrator is typically a product that includes a heat source (and/or cooling) that can be controlled into the desired temperature. You insert the temperature sensor to be calibrated and a traceable accurate reference sensor into the heat source and compare the readings at different temperatures.

Unfortunately, there is no international standard that would specify what a temperature calibrator is. Therefore, we see the word “temperature calibrator” being used in various different contexts.

A temperature calibrator can also be electrical devices that can measure and/or simulate temperature sensor signals, not containing any heat source. These sensor signals are typically resistance (for RTD sensors) or voltage (for thermocouples). The temperature calibrator knows the sensor formulas so it can convert and display these signals in temperature unit for convenient use.

In some cases, even relatively simple devices, such as temperature indicator, may be called temperature calibrators.

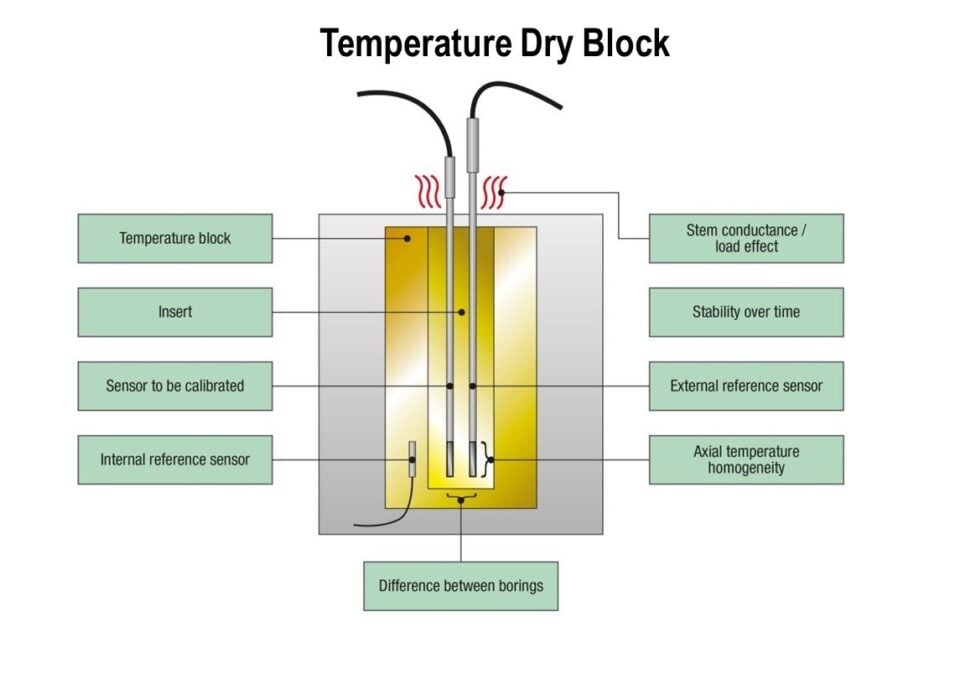

A temperature dry-block (or dry well) is a product that can heat and/or cool a metal block where suitable holes have been drilled for inserting temperature sensors. The holes need to be a tight fit to ensure proper temperature transfer. If the hole is too large, there will be air between the block and sensor, causing measurement error. The holes in the block are “dry”, so there is no liquid inside the holes. Typically, replaceable inserts are used in dry blocks for different kinds of sensors.

The benefits of a dry block include that they are typically portable (small and light), fast to use and they don’t get messy as no liquids are being used.

A temperature bath is a heat source that has liquid inside (water, oil, ethanol). The liquid is heated/cooled into the desired temperature and the sensors to be calibrated can be inserted into the liquid. The liquid is typically stirred for best homogeneity.

The befits of a bath is that you can insert different shapes of sensors into it, several at one time, and the homogeneity is very good. The drawback is that a bath is normally pretty large and heavy, temperature changes slowly and it may be messy to work with different liquids.

Temperature sensors/probes are instruments that are used to measure temperature. They typically have an electrical output proportional to the temperature they are measuring.

To calibrate a temperature sensor/probe, you will need to immerse it into an accurate known temperature and compare the output signal to the nominal output signal. It is not possible to simulate temperature, it needs to be created with a temperature source.

So, this calibration includes a documented comparison of the sensor output to the accurate temperature.

Temperature sensors cannot typically be adjusted/trimmed, but you may use correction coefficients to compensate for the found error.

A temperature transmitter is an instrument that measures temperature with the help of a temperature sensor and outputs a signal proportional to the input temperature. Often, in process instrumentation, the output signal is a 4 to 20 mA current signal.

To calibrate (check accuracy) of a temperature transmitter you can simulate the temperature sensor signal as input to the transmitter and simultaneously measuring the output signal the transmitter generates. Then you compare the input and output signals and see if the transmitter is working accurately.

Watch this video to learn how to calibrate RTD temperature transmitters.