Overview

One of the largest public utilities in the United States, the Miami-Dade Water and Sewer Department (WASD), a department of Miami-Dade County, provides direct service to more than 420,000 customers and employs more than 2,500 workers. In addition, the department provides water and wastewater service to the unincorporated areas of Miami-Dade County, wholesale water service to 15 municipalities and wholesale wastewater service to 12 municipalities. The department draws approximately 347 million gallons of water every day from the Biscayne Aquifer for consumer use. Currently, the annual operating revenues are in excess of $546 million.

A big responsibility

The body weight of a human is more than two thirds water. Without consuming water, death would be certain after a few days. In Miami-Dade, water is everywhere, but no one should take access to clean, fresh water for granted, as it is imperative to survival. Needless to say, Miami-Dade WASD has a big responsibility to its 2.3 million population. Accurate calibration is vital to the entire operation.

Plant instrument technicians calibrate flow, level, pressure, temperature, analytical, and safety leak detection instrumentation. Calibration accomplishes several crucial activities at Miami-Dade WASD: Ensures optimal performance of instruments, allowing the highest standard of water treatment. Creates a safe environment for personnel and produces a quality product for consumers. Meets industry regulations by providing data traceability and accountability.

Maintaining quality and lowering risks

The plant instrument technicians must calibrate to maintain the plant’s measurement equipment. When instruments are functioning at optimal performance, it ensures quality and an efficient water treatment process. In turn, they are able to provide the best water treatment possible. The risks of not calibrating instruments could have detrimental effects on the treatment of the drinking water. For instance, chemical dosing levels for disinfecting are adjusted based on flow measurements taken from the incoming raw water wells. The water softening process is also affected, which includes the pH level. Even small errors over time will affect the quality of the treatment. Level instrument calibrations affect how Miami-Dade WASD manages the chemical inventory. Proper calibration of instruments creates a safe environment for personnel and minimizes risks. If an instrument is not functioning properly, the equipment is unreliable; and the entire process could be jeopardized. Incorrect measurements could endanger lives, putting the technicians and customers in harm’s way.

Accurate data documentation provides full traceability and accountability to federal, state and local agencies and wholesale water customers. As with any drinking water treatment facility, Miami-Dade WASD reports to several government agencies that monitor the effect of human health and environmental impact. For example, the South Florida Water Management District monitors how much ground water is drawn from the Biscayne Aquifer. Miami-Dade WASD is required to calibrate the entire well and plant raw water flow meters, which measure how much water is drawn from the aquifer. To minimize impact and still meet the needs of the community, limits or caps have been applied. Miami-Dade WASD is required to submit calibration certificates and report the total amount drawn.

A complete solution

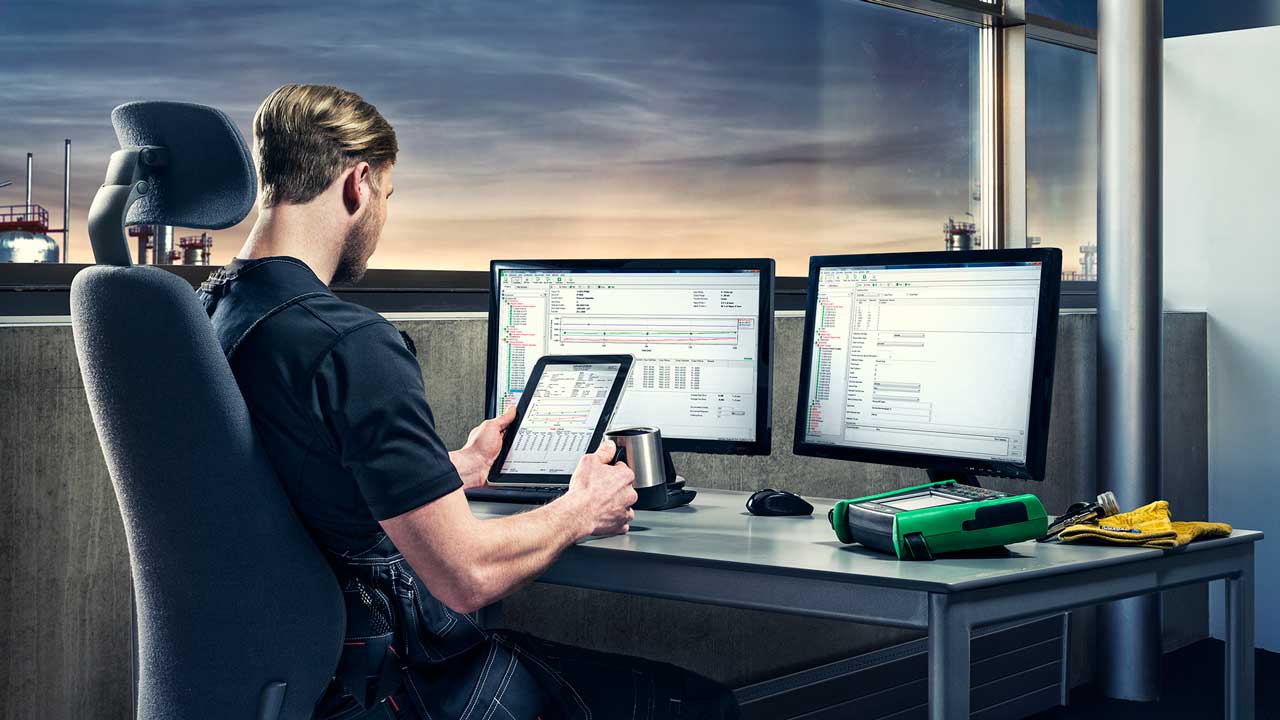

Julio R. Hernandez, a Plant Instrument Technician at Miami-Dade WASD, was in search of the best calibration equipment in the industry, that could streamline calibration and documentation methods, while standardizing the equipment used. He needed multifunction, documenting, robust, and easy to use calibrators.

“Prior to using Beamex equipment, our old documenting process needed to be updated. It was not anything we could standardize on. We began looking at software and found another brand. The software looked robust but needed to be customized. We wanted something that organized data like a Windows Explorer type of environment. In conversations with the local Beamex distributor, we mentioned we were looking for better calibration software. The Beamex distributor demoed their products, and the rest is history,” Julio describes.

Today, Miami-Dade WASD utilizes the Beamex MC5 multifunctional documenting calibrators and CMX professional calibration management software, part of the Beamex integrated calibration solution. The MC5s calibrate the most important plant instruments. CMX is integrated with Miami-Dade WASD’s maintenance management software, Infor EAM Enterprise edition, to schedule, perform maintenance and document results. “A maintenance management software system can record, and archive work performed, but it will never be very suitable for calibration specific tasks,” Julio explains. The maintenance management software is designed to manage all the other aspects of maintaining an industrial facility but does not typically provide the in-depth tool for managing calibration.

Overall, Miami-Dade WASD and their technicians benefit from a simplified, standardized calibration program. The combination of multifunctional documenting calibrators and CMX calibration software has automated the entire process. Miami-Dade WASD has experienced at least a 50% efficiency improvement to their calibration procedures. For the department, the system has formed a documenting system that can be shared on a network; provide better reporting, and a standardized, secure format. The quality of calibrations has increased as errors have been minimized. “Beamex is a very complete calibration specific company, with excellent products, factory support and training. Beamex does not cover just the equipment, but provides excellent software to complement the instruments. The software is very robust, reliable with great features, which are easy to use,” Julio explains.

Plans for growth

The ultimate goal of the entire calibration program at Miami-Dade WASD is implementation in all treatment plants, instrument shops and some meter calibration shops. Today, there is only one facility that has not utilized the Beamex integrated calibration solution. Julio notes, ”We still have some more work to do, as our department is growing and not all plants are using it to the full extent yet. The overall experience has been positive.” He expects that CMX will be deployed at the last plant within the next six months and it will be used extensively. Julio also looks forward to purchasing the new Beamex MC6 advanced field calibrator and communicator in the near future.